3sr+buyer

Active Member

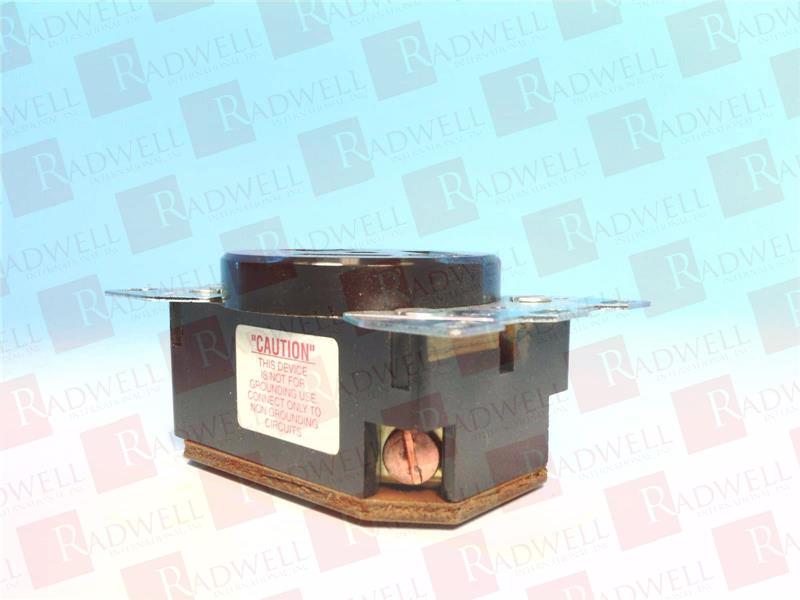

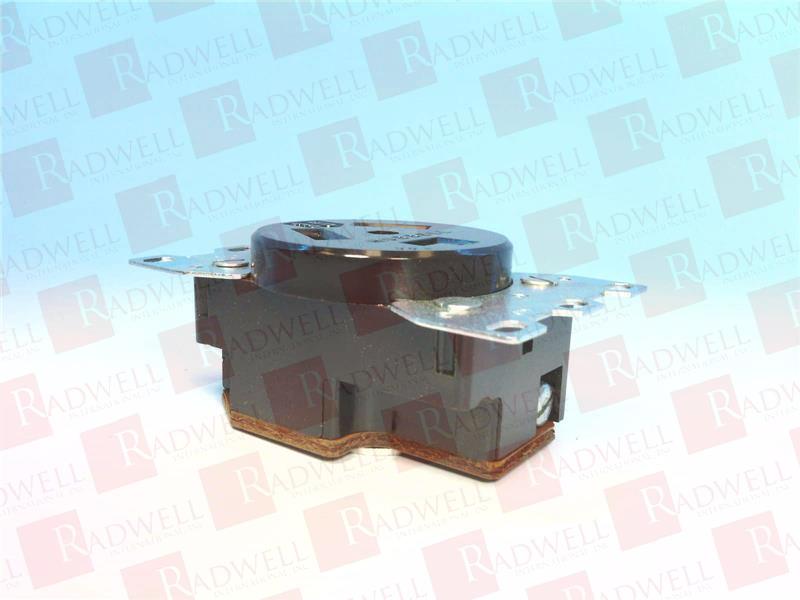

Wall plug temperature too high suggests poor contact between the plug blades and outlet contacts. Check the plug blades and outlet contacts for corrosion, and check the outlet contacts for misalignment or looseness. If the outlet contacts are steel instead of brass or are not full size, that can also increase heat.

Poor wire clamping can also increase heat, but that would be on the back of the outlet and less detectable by the plug heat sensor.