I had a misspent youth in the maritime world before moving on to the easier world of aviation.This thread doesnt affect me bein in NA. Just wanted to say your attention to detail and knowledge about the vessels and shipping industry is pretty fascinating Mr. Miserable. Thanks for posting up the information. Do you have a career in the field or just a hobby?

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2020 Shipping Movements

- Thread starter Mr Miserable

- Start date

GLOVIS CRYSTAL has now come within range of land based AIS receivers 40nm SW of the Scilly Isles.

You are right. She has made some unusual course changes.Depends where you start the line. She wasn't on a rhumb line when she exited Mona like GLOVIS CRYSTAL was.

Shipping containers in various guises have been around since the 1800’s but it was an American trucker called Malcolm McLean that devised in the mid 1950’s the modern intermodal container - a container that could be loaded quickly and securely onto ships, onto railcars and onto road trailers. Its effect was to greatly reduce transportation costs and to significantly increase the speed of transporting goods. To facilitate the container, ships were initially modified, then redesigned and finally purpose built to transport as many containers as possible within constraints of cost and ship size.

Containerisation affected ports too. San Francisco was a big bustling port (Teslas are shipped from Pier 80) but there wasn’t room to park the thousands of containers and so it quickly went into decline and instead, across the other side of the San Francisco Bay, the new port of Oakland with its big cranes, rail yard and acres of land given over to holding stacks of containers, quickly became the cargo hub of the US west coast. Tesla Model S and X are shipped from here to Europe by rail and to Australia and New Zealand by ship in standard 40’ containers.

Every year it is estimated that of the 220 million containers that are transported globally by ship about 1,300 are lost overboard. In percentage terms it’s tiny and barely worth considering (0.00006%) So insuring them is not a bad business to be in. Many of those container losses are due to major accidents when a ship sinks but hundreds are lost in individual ‘minor’ incidents when a ship loses one or two containers overboard often in bad weather. The numbers suggest then that it’s a frequent occurrence. Indeed, readers of the Daily Mail will recognise the regular story of rubber ducks, Nike trainers and Lego being washed up on our shores from containers that have been lost at sea. Anyone who has ever shipped anything by container will have been offered the opportunity buy extra insurance specifically to cover the loss of the container overboard and so for the insurance industry at least, container losses provide lucrative business.

The trouble with losing a container overboard is not just it’s loss and the commercial loss of it’s contents. The containers often do not sink and can float around being a major safety hazard to shipping. Even more dangerous are containers that partially sink or float just beneath the surface. These subsurface containers are every yachtsman’s greatest fear since hitting one of these invisible objects can easily rip the keel off and capsize their boat in an instant. Just last week one of the yachts taking part in the Vendee Globe round the world yacht race had to retire after hitting an unknown underwater object. She was very lucky that her keel remained attached.

However last week a ship called ONE APUS lost no less than 1,900 containers overboard in one go during a storm 1600nm NW of Hawaii. Of those 1,900 containers 64 of them (so far) have been classified as carrying dangerous cargo. The environmental cost is still to be determined but is unlikely to be addressed.

In 1912 the passenger shipping industry was given a wake-up call as a result of the sinking of the TITANIC and as a result the International Convention for the Safety of Life at Sea came into being in 1914 which set new standards of safety. This convention has been subject to continuous amendment and improvement over the years. The tragic disaster also led to the foundation of the International Ice Patrol which even now monitor and report on icebergs in the busy North Atlantic and the convention of a continual monitoring of a radio by ships at sea to listen for distress calls.

The ONE APUS incident needs to become the impetus for the international shipping industry to take the issue of container losses at sea much more seriously and to solve the problem once and for all. The problem hasn’t been entirely ignored but regulations concerning the weight and balance of containers, their packing and lashing are slowly being tweaked. The mandatory reporting of the loss of a container at sea would also highlight the true scale of the problem and may also help in locating them before they become a hazard.

The elephant in the room which remains unaddressed is the poor construction of some containers which can cause them to collapse when stacked. It’s time that nettle was firmly grasped and in the absence of international agreement, the shipping lines/ports need to take the lead by being satisfied that each container they handle has a proven construction pedigree.

Containerisation affected ports too. San Francisco was a big bustling port (Teslas are shipped from Pier 80) but there wasn’t room to park the thousands of containers and so it quickly went into decline and instead, across the other side of the San Francisco Bay, the new port of Oakland with its big cranes, rail yard and acres of land given over to holding stacks of containers, quickly became the cargo hub of the US west coast. Tesla Model S and X are shipped from here to Europe by rail and to Australia and New Zealand by ship in standard 40’ containers.

Every year it is estimated that of the 220 million containers that are transported globally by ship about 1,300 are lost overboard. In percentage terms it’s tiny and barely worth considering (0.00006%) So insuring them is not a bad business to be in. Many of those container losses are due to major accidents when a ship sinks but hundreds are lost in individual ‘minor’ incidents when a ship loses one or two containers overboard often in bad weather. The numbers suggest then that it’s a frequent occurrence. Indeed, readers of the Daily Mail will recognise the regular story of rubber ducks, Nike trainers and Lego being washed up on our shores from containers that have been lost at sea. Anyone who has ever shipped anything by container will have been offered the opportunity buy extra insurance specifically to cover the loss of the container overboard and so for the insurance industry at least, container losses provide lucrative business.

The trouble with losing a container overboard is not just it’s loss and the commercial loss of it’s contents. The containers often do not sink and can float around being a major safety hazard to shipping. Even more dangerous are containers that partially sink or float just beneath the surface. These subsurface containers are every yachtsman’s greatest fear since hitting one of these invisible objects can easily rip the keel off and capsize their boat in an instant. Just last week one of the yachts taking part in the Vendee Globe round the world yacht race had to retire after hitting an unknown underwater object. She was very lucky that her keel remained attached.

However last week a ship called ONE APUS lost no less than 1,900 containers overboard in one go during a storm 1600nm NW of Hawaii. Of those 1,900 containers 64 of them (so far) have been classified as carrying dangerous cargo. The environmental cost is still to be determined but is unlikely to be addressed.

In 1912 the passenger shipping industry was given a wake-up call as a result of the sinking of the TITANIC and as a result the International Convention for the Safety of Life at Sea came into being in 1914 which set new standards of safety. This convention has been subject to continuous amendment and improvement over the years. The tragic disaster also led to the foundation of the International Ice Patrol which even now monitor and report on icebergs in the busy North Atlantic and the convention of a continual monitoring of a radio by ships at sea to listen for distress calls.

The ONE APUS incident needs to become the impetus for the international shipping industry to take the issue of container losses at sea much more seriously and to solve the problem once and for all. The problem hasn’t been entirely ignored but regulations concerning the weight and balance of containers, their packing and lashing are slowly being tweaked. The mandatory reporting of the loss of a container at sea would also highlight the true scale of the problem and may also help in locating them before they become a hazard.

The elephant in the room which remains unaddressed is the poor construction of some containers which can cause them to collapse when stacked. It’s time that nettle was firmly grasped and in the absence of international agreement, the shipping lines/ports need to take the lead by being satisfied that each container they handle has a proven construction pedigree.

ParHunter

Member

Another fun fact for containers is that shippers often did not update the total weight of the containers. So they booked their containers saying they weigh about 20,000kg and when they were loaded they actually had e.g. 25,000kg. Doesn't cause a problem with a few containers but there were cases apparently (Mr Miserable do you know the specifics?) where ships sank because the total of the cargo was too high because most containers where overloaded. In 2017 a new regulation - SOLAS VGM - came into force that each Shipper has to have their containers weight and sign for it before they are allowed to be loaded on board.

ParHunter

Member

So why is the Glovis Crystal not stopping at Southampton first given that she is sailing past it. I assume she won't return to the US directly from Southampton (after Zeebrugge)? I assume she will pick up cars for the US market first. Where would she load these? I would assume Bremerhaven. Are there lots of exports via Zeebrugge as well?

graceyellow

New Member

hello. i am new to the forum. i ordered a sr+ mid november and got a delivery date fornext week. this post had given me so much fun while waiting for the delivery. i got to know from here that my car must have been on one of the ships from china. i thought i was done when they both arrived in europe december 6th. then during weekend the danish government (we live in denmark) announced that they are not going to increase the electrical car registration tax next year! So we redecided, canceled the order for the sr+, and placed a new order for the long range. the website shows that scheduled delivery will be feburuary which is fine since we don't really need two cars during covid. so i restarted my daily check of this post. eager to see which boat our new car will be on

Looks like the Glovis Crystal just picked up a channel pilot from Brixham. I guess the pilot will stay throughout the voyage to Zebrugge and back to Southampton? Do they then also pick up a Zebrugge (and Southampton?) specific pilot when getting ready to dock too? I can see why ship bridges are so big..

Interesting article I found on channel pilots: English Channel pilots enhance safety in world's busiest waterway - Ocean Navigator

Interesting article I found on channel pilots: English Channel pilots enhance safety in world's busiest waterway - Ocean Navigator

Attachments

The ship is chartered to Tesla and Tesla want the bulk of the cars unloaded in Zeebrugge first and then the RHD versions unloaded in Southampton afterwards. The ship then returns to the Hyundai Glovis fleet and in this case she will load in Bremerhaven, Hamburg, Southampton and Antwerp before heading off to the Middle East. Zeebrugge is the largest vehicle handling port in the world - well worth a look on Google satellite view to get an idea of the size of the operation there which handles imports as well as exports.So why is the Glovis Crystal not stopping at Southampton first given that she is sailing past it. I assume she won't return to the US directly from Southampton (after Zeebrugge)? I assume she will pick up cars for the US market first. Where would she load these? I would assume Bremerhaven. Are there lots of exports via Zeebrugge as well?

Looks like the Glovis Crystal just picked up a channel pilot from Brixham. I guess the pilot will stay throughout the voyage to Zebrugge and back to Southampton? Do they then also pick up a Zebrugge (and Southampton?) specific pilot when getting ready to dock too? I can see why ship bridges are so big..

Interesting article I found on channel pilots: English Channel pilots enhance safety in world's busiest waterway - Ocean Navigator

You are correct. The DW pilot will generally stay onboard until it departs European waters. These are highly qualified and experienced captains who are able to spend a little more time at home than they would have if they were a Master of a large ship. They will pick up a port pilot at each port too. This is generally a requirement of each port. Some bridge crew can become qualified to be a pilot for a specific port but this option is generally reserved for ferries and is at the discretion of the port authorities.

Interestingly, I posted a link on here to that same article on the 9 Nov.

Yes.How come some take a pilot and some don't? Is it the experience of the crew in that area?

Watts_Up

Well-Known Member

Containerization affected ports too. San Francisco was a big bustling port (Teslas are shipped from Pier 80)

but there wasn’t room to park the thousands of containers and so it quickly went into decline and instead,

across the other side of the San Francisco Bay, the new port of Oakland with its big cranes, rail yard and acres of land

given over to holding stacks of containers, quickly became the cargo hub of the US west coast.

Tesla Model S and X are shipped from here to Europe by rail and to Australia and New Zealand by ship in standard 40’ containers.

About the European versions of the Model S and X, I believe they are still finally assembled in Tilburg, in the Netherlands.

- The car frames arrive from the factory in Fremont, California, with the interior fully fitted.

- The battery pack and electric drive-train components are shipped separately, from I guess the Tesla Giga factory in Nevada.

Which explains the use of containers for those models by opposition to the Model 3 and Y.

Last edited:

About the European versions of the Model S and X, I believe they are still finally assembled in Tilburg, in the Netherlands.

- The car frames arrive from the factory in Fremont, California, with the interior fully fitted.

- The battery pack and electric drive-train components are shipped separately, from I guess the Tesla Giga factory in Nevada.

Which explains the use of containers for those models by opposition to the Model 3 and Y.

It's import tax driven. They import the car parts to Tilburg - even if the whole car is in the container - and assemble in Tilburg to avoid EU import tax on cars.

In a bit exaggerated form; there could be a fully assembled car in the container and the steering wheel as a loose part in the same container as long as final assembly is done in Tilburg. To avoid taxation.

JupiterMan

Active Member

I guess this Tilburg process will need to change once the Plaid (and later I assume all S / X) comes online, with the integrated battery?- The battery pack and electric drive-train components are shipped separately, from I guess the Tesla Giga factory in Nevada.

GLOVIS CRYSTAL Overtook the RCC AMSTERDAM in the small hours of this morning and later picked up a pilot off Brixham.

She is currently about 20nm SW of the Isle of Wight and heading at full speed towards Zeebrugge.

She is scheduled to dock in Zeebrugge around midnight tonight.

I have already voiced my worry that the work scheduled to take place on the P Vandamme lock may delay her further however the sudden burst of speed makes me think she has an agreed rendezvous time to make with the Zeebrugge pilot and so all may be OK.

She is due to arrive into Southampton on Thursday afternoon.

RCC AMSTERDAM spent the last 18 hours sulking off the Cornish coast.

She is currently heading south about 40nm south of the Lizard and it looks as though she intends to shortly join the shipping lane eastwards. She may pick up a pilot off Cherbourg (where they are delivered by helicopter).

She is not due in to Zeebrugge until tomorrow night and so a leisurely sail up the Channel is in store.

She was booked to arrive in Southampton on Friday morning at 1130 however this booking is no longer appearing on the Southampton board.

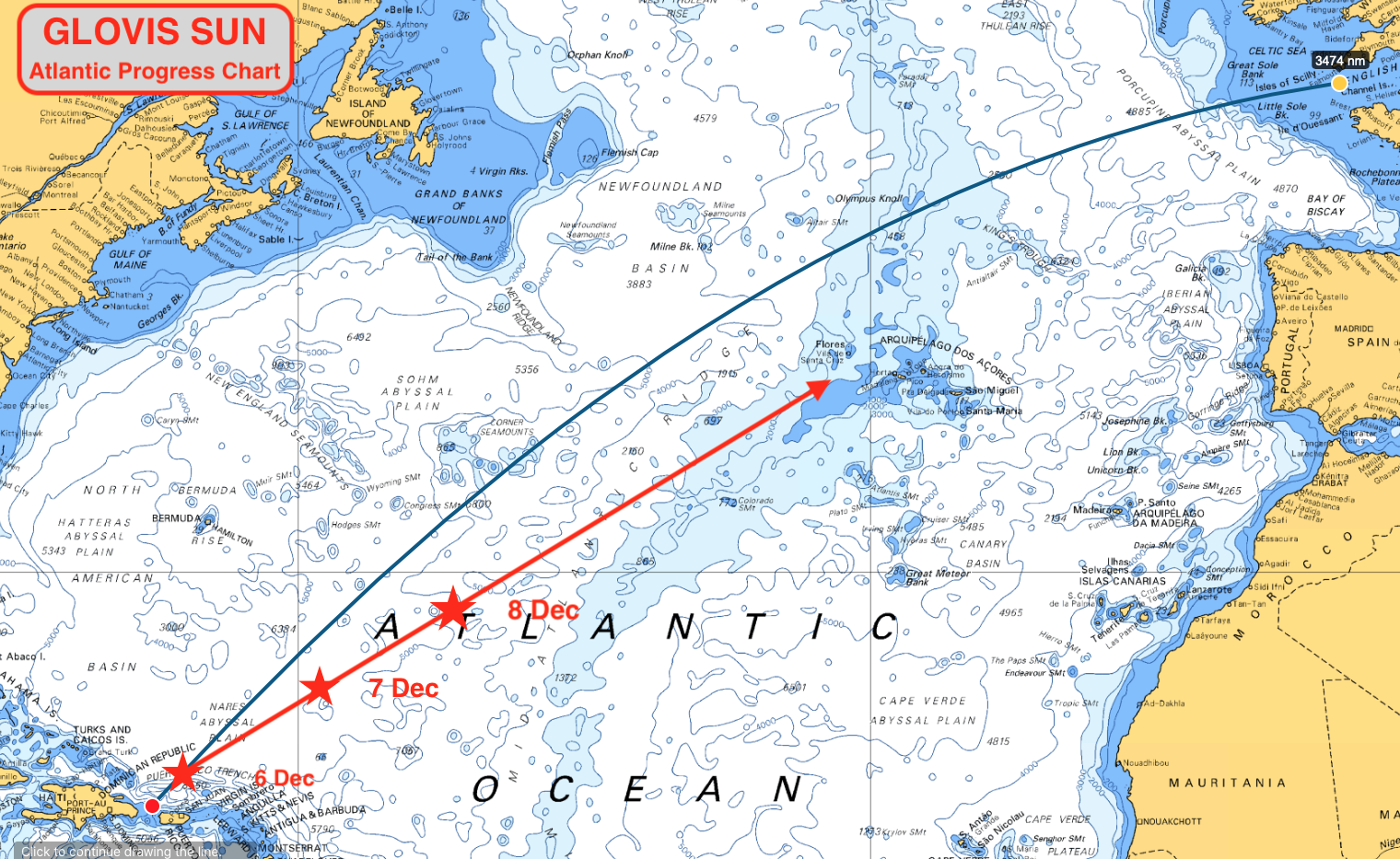

GLOVIS SUN is continuing to maintain 18kts on a heading of 061 degrees.

This is a rhumb line course similar to what GLOVIS CRYSTAL took initially however in this instance it looks far more intentional.

The course should take her between the islands of the Azores and in doing so will avoid some heavy weather to the north west.

Her estimate for Zeebrugge remains 15 Dec

LYDDEN is also maintaining a rhumb line course of 090 at nearly 20kts.

In her case it is to avoid a violent storm that is approaching from the south west.

By keeping much more south than normal she will hopefully be clear of the worst of the weather.

Nevertheless it does look like that she may experience some rough weather ahead.

The big news was that she changed her destination from Zeebrugge to Amsterdam yesterday.

Her AIS is showing that she aims to arrive in Amsterdam at 0900 on 14 Dec - a very ambitious ETA.

She is currently about 20nm SW of the Isle of Wight and heading at full speed towards Zeebrugge.

She is scheduled to dock in Zeebrugge around midnight tonight.

I have already voiced my worry that the work scheduled to take place on the P Vandamme lock may delay her further however the sudden burst of speed makes me think she has an agreed rendezvous time to make with the Zeebrugge pilot and so all may be OK.

She is due to arrive into Southampton on Thursday afternoon.

RCC AMSTERDAM spent the last 18 hours sulking off the Cornish coast.

She is currently heading south about 40nm south of the Lizard and it looks as though she intends to shortly join the shipping lane eastwards. She may pick up a pilot off Cherbourg (where they are delivered by helicopter).

She is not due in to Zeebrugge until tomorrow night and so a leisurely sail up the Channel is in store.

She was booked to arrive in Southampton on Friday morning at 1130 however this booking is no longer appearing on the Southampton board.

GLOVIS SUN is continuing to maintain 18kts on a heading of 061 degrees.

This is a rhumb line course similar to what GLOVIS CRYSTAL took initially however in this instance it looks far more intentional.

The course should take her between the islands of the Azores and in doing so will avoid some heavy weather to the north west.

Her estimate for Zeebrugge remains 15 Dec

LYDDEN is also maintaining a rhumb line course of 090 at nearly 20kts.

In her case it is to avoid a violent storm that is approaching from the south west.

By keeping much more south than normal she will hopefully be clear of the worst of the weather.

Nevertheless it does look like that she may experience some rough weather ahead.

The big news was that she changed her destination from Zeebrugge to Amsterdam yesterday.

Her AIS is showing that she aims to arrive in Amsterdam at 0900 on 14 Dec - a very ambitious ETA.

The Model S and X are fully manufactured in Fremont and tested before being dismantled into about 3 pieces and loaded into containers and shipped to Europe. If I recall correctly they squeeze 4 Model S into each container whereas they can only fit 3 Model X into a single container.About the European versions of the Model S and X, I believe they are still finally assembled in Tilburg, in the Netherlands.

- The car frames arrive from the factory in Fremont, California, with the interior fully fitted.

- The battery pack and electric drive-train components are shipped separately, from I guess the Tesla Giga factory in Nevada.

Which explains the use of containers for those models by opposition to the Model 3 and Y.

ParHunter

Member

Nice pictures of the ONE Apus that lost plenty of containers:

ONE Apus Update: Photos Show Cargo Carnage as Containership Arrives in Kobe – gCaptain

ONE Apus Update: Photos Show Cargo Carnage as Containership Arrives in Kobe – gCaptain

I don't expect a shipment for Fremont until about 10 January at the earliest. I'm not sure how the current COVID restrictions in California will affect production and the logistics chain. It would be glib and naive to suggest they will have no affect. The current infection rate and hospitalisations would suggest that January in the USA is not going to be pleasant.hello. i am new to the forum. i ordered a sr+ mid november and got a delivery date fornext week. this post had given me so much fun while waiting for the delivery. i got to know from here that my car must have been on one of the ships from china. i thought i was done when they both arrived in europe december 6th. then during weekend the danish government (we live in denmark) announced that they are not going to increase the electrical car registration tax next year! So we redecided, canceled the order for the sr+, and placed a new order for the long range. the website shows that scheduled delivery will be feburuary which is fine since we don't really need two cars during covid. so i restarted my daily check of this post. eager to see which boat our new car will be on

Just checked on the Zeebrugge shipment timetable. RCC Amsterdam is due to arrive at 9th December 8am gmt and won't depart until 11th December 6am (but this is not booked in at Southampton)

Glovis Crystal is due to arrive in zeebruge at midnight tonight and will depart at 10pm tomorrow and is due to arrive in Southampton at 20:20 on 10th December.

I wonder whats going on with RCC Amsterdam?

Glovis Crystal is due to arrive in zeebruge at midnight tonight and will depart at 10pm tomorrow and is due to arrive in Southampton at 20:20 on 10th December.

I wonder whats going on with RCC Amsterdam?

Similar threads

- Replies

- 912

- Views

- 62K

- Replies

- 5K

- Views

- 559K

- Replies

- 10K

- Views

- 2M

- Replies

- 14

- Views

- 1K

- Replies

- 6K

- Views

- 1M