Hi all,

I'd appreciate your thoughts. I'm getting my wall connector installed soon. I live in New England, and will mount the connector on a post next to my driveway.

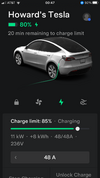

The electrician would like to use a 50 amp breaker, not a 60. The charge speed penalty would be from 44 mph at 60 amp, to 37 mph at 50 amp. That seems pretty close, and I don't anticipate needing top recharging speeds as my daily use is mostly around town/short trips. Should I go along with the lower amp set-up?

He also wants to use aluminum wire. He says that the wire size needed means it will cost 2x more, at least, in copper and be more difficult to route. I noticed on page 5 of the installation manual, it says “COPPER WIRE TERMINATIONS ONLY for landing in Wall Connector wirebox terminals. Conductors can be stranded or solid.” Does this mean that the wire can be aluminum, but the “terminations” copper? The connector will be mounted 6' from the house, and about 30' total from the panel.

Thanks for your comments in advance!

I'd appreciate your thoughts. I'm getting my wall connector installed soon. I live in New England, and will mount the connector on a post next to my driveway.

The electrician would like to use a 50 amp breaker, not a 60. The charge speed penalty would be from 44 mph at 60 amp, to 37 mph at 50 amp. That seems pretty close, and I don't anticipate needing top recharging speeds as my daily use is mostly around town/short trips. Should I go along with the lower amp set-up?

He also wants to use aluminum wire. He says that the wire size needed means it will cost 2x more, at least, in copper and be more difficult to route. I noticed on page 5 of the installation manual, it says “COPPER WIRE TERMINATIONS ONLY for landing in Wall Connector wirebox terminals. Conductors can be stranded or solid.” Does this mean that the wire can be aluminum, but the “terminations” copper? The connector will be mounted 6' from the house, and about 30' total from the panel.

Thanks for your comments in advance!