EstebanP212

Member

To many people think of gruber first and they mostly busy with roadstersSeems I need to talk to my PR team...

Ya upload on YouTube of customer repairs to get exposure

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

To many people think of gruber first and they mostly busy with roadstersSeems I need to talk to my PR team...

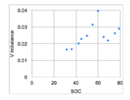

Yeah I'm interested in this too. I haven't seen anyone mention what size imbalance becomes a problem. Or how fast it can progress from small imbalance to large imbalance.I'm curious what the voltage difference that is considered an imbalance? I have a 2014 P85+ with 90k miles and my average cell difference is .005v.

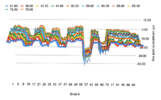

Thanks so much for your insight! That's very helpful.Voltage imbalance is only about 1/4 of the picture. You can have a massive voltage imbalance at various SoC, but as long as other variables line up it doesn't matter. What matters more is CAC imbalance, or actual capacity of the cell group. The BMS calculates this per group, so it can estimate where voltages will land at various SoC. The BMS also keeps track of cell impedance, and per-group load profiles, among other things. It will calculate the max safe load/charge and allow it to continue to operate provided no safety issues.

A voltage imbalance itself might not cause issues under load/charge. While there are hard limits on this as a single metric (usually between 60-100mV imbalance while avg pack voltage is in the 3.5-3.8V range, depending on pack type and a few other factors), these are less common to hit than things related to the overall picture. For example, if a cell group is higher than the rest, under load it will likely sag to within a small % of the rest of the pack, and thus not really an issue. It'll also be likely to end up flipping to a lower voltage than the rest near lower SoC, indicating a weaker group. The BMS is able to calculate the window of usable power and energy based on everything it knows, show that on the dash as your range number, and generally you're none the wiser even if it's locking out a small portion of energy to keep things useful and safe.

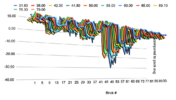

The issue becomes when that window shrinks to a point where the BMS feels that a normal driving load could cause a safety concern in pushing a cell group out of spec of pulling too much power from a particular group, for example. Many of the "Maximum Charge Level Reduced" errors are the result of one or two cell groups just finally crossing a threshold that makes that operating window too tight for normal operation. A lot of them also end up being physical issues with modules that have more quickly pushed them out of the safe window, such as corrosion from moisture ingress... in which case the pack will very quickly lose more and more usable capacity with every cycle.

Overall, while a persistent imbalance can likely indicate a weak or strong cell group relative to the rest of the pack, it's not necessarily an indication of a problem. Can be, but not always. You really need the rest of the data, which the BMS unfortunately isn't normally happily divulge on CAN.

The 057 Tech Battery Monitoring Device that goes along with our extended service plans tries to gather more of the picture and come up with a better overall health estimate for the cell groups and pack as a whole by using some proprietary methods for coaxing more information than normal from the BMS. The vast majority of packs are perfectly fine, even with some voltage imbalance, as long as its within the limits of the BMS. It's the trends on this that tend to matter. If things are trending towards being outside the BMS's abilities, then this would be an issue. Most all batteries are trending this way, but at different rates. Some at a rate where issues won't occur for decades, others are a rate where you're going to be stuck in a few months or less. (We're actually considering exposing an estimated date range for this on the BMD dashboard for customers once enough data is collected to assess the trends.) There's just no way to really know based on passive CAN monitoring of group voltages alone.

Funny enough, it seems Tesla really doesn't like us gathering this data from customer vehicles and exposing it for them. We know for sure that Tesla themselves has at least one of our BMDs, and they've actually released a BMS OTA for some older S's somewhat recently that appears to have the sole purpose of obfuscating some of this data and the method we were using to gather it. Fortunately, the S/X BMS is an open book to me nowadays, so tracking these changes and updating the BMDs accordingly isn't a huge issue and there's not much they can do long term on this without hardware changes to older cars (not happening).

Anyway, bottom line is that voltage is only one small piece of the puzzle.

Oh, that is the reason for the "bug fixes" we keep getting lately. You're the bug, and they are trying to squash you.Funny enough, it seems Tesla really doesn't like us gathering this data from customer vehicles and exposing it for them. We know for sure that Tesla themselves has at least one of our BMDs, and they've actually released a BMS OTA for some older S's somewhat recently that appears to have the sole purpose of obfuscating some of this data and the method we were using to gather it. Fortunately, the S/X BMS is an open book to me nowadays, so tracking these changes and updating the BMDs accordingly isn't a huge issue and there's not much they can do long term on this without hardware changes to older cars (not happening).

Voltage imbalance is only about 1/4 of the picture. You can have a massive voltage imbalance at various SoC, but as long as other variables line up it doesn't matter. What matters more is CAC imbalance, or actual capacity of the cell group. The BMS calculates this per group, so it can estimate where voltages will land at various SoC. The BMS also keeps track of cell impedance, and per-group load profiles, among other things. It will calculate the max safe load/charge and allow it to continue to operate provided no safety issues.

A voltage imbalance itself might not cause issues under load/charge. While there are hard limits on this as a single metric (usually between 60-100mV imbalance while avg pack voltage is in the 3.5-3.8V range, depending on pack type and a few other factors), these are less common to hit than things related to the overall picture. For example, if a cell group is higher than the rest, under load it will likely sag to within a small % of the rest of the pack, and thus not really an issue. It'll also be likely to end up flipping to a lower voltage than the rest near lower SoC, indicating a weaker group. The BMS is able to calculate the window of usable power and energy based on everything it knows, show that on the dash as your range number, and generally you're none the wiser even if it's locking out a small portion of energy to keep things useful and safe.

The issue becomes when that window shrinks to a point where the BMS feels that a normal driving load could cause a safety concern in pushing a cell group out of spec of pulling too much power from a particular group, for example. Many of the "Maximum Charge Level Reduced" errors are the result of one or two cell groups just finally crossing a threshold that makes that operating window too tight for normal operation. A lot of them also end up being physical issues with modules that have more quickly pushed them out of the safe window, such as corrosion from moisture ingress... in which case the pack will very quickly lose more and more usable capacity with every cycle.

Overall, while a persistent imbalance can likely indicate a weak or strong cell group relative to the rest of the pack, it's not necessarily an indication of a problem. Can be, but not always. You really need the rest of the data, which the BMS unfortunately isn't normally happily divulge on CAN.

The 057 Tech Battery Monitoring Device that goes along with our extended service plans tries to gather more of the picture and come up with a better overall health estimate for the cell groups and pack as a whole by using some proprietary methods for coaxing more information than normal from the BMS. The vast majority of packs are perfectly fine, even with some voltage imbalance, as long as its within the limits of the BMS. It's the trends on this that tend to matter. If things are trending towards being outside the BMS's abilities, then this would be an issue. Most all batteries are trending this way, but at different rates. Some at a rate where issues won't occur for decades, others are a rate where you're going to be stuck in a few months or less. (We're actually considering exposing an estimated date range for this on the BMD dashboard for customers once enough data is collected to assess the trends.) There's just no way to really know based on passive CAN monitoring of group voltages alone.

Funny enough, it seems Tesla really doesn't like us gathering this data from customer vehicles and exposing it for them. We know for sure that Tesla themselves has at least one of our BMDs, and they've actually released a BMS OTA for some older S's somewhat recently that appears to have the sole purpose of obfuscating some of this data and the method we were using to gather it. Fortunately, the S/X BMS is an open book to me nowadays, so tracking these changes and updating the BMDs accordingly isn't a huge issue and there's not much they can do long term on this without hardware changes to older cars (not happening).

Anyway, bottom line is that voltage is only one small piece of the puzzle.

Oh, that is the reason for the "bug fixes" we keep getting lately. You're the bug, and they are trying to squash you.

edit: Or is this just a hidden update not included with firmware?

We have a 2013 S here with "Maximum Charge Level Reduced" error. HV Battery had some issues and has been fixed now, but can't figure out a way to reset that alert.

Would you help us out here? For payment of course. I'm in Europe, so no way to get the car to you.

Would love this…We're actually considering exposing an estimated date range for this on the BMD dashboard for customers once enough data is collected to assess the trends…

Normal OTA. There were virtually no changes to the BMS other than this stuff to hide data.

"Fixed" is unlikely in this case, so no probably not. Unless the fault is with hardware and not related to a CAC imbalance (this has been less than 5% of cases in my experience), then nothing has actually been "fixed" and no reset will solve the issue.

Out of the many packs we've done, the common places seem to be the side vents on either side of the car, usually near the front and front center, suggesting front tire road spray near the failed vents is a likely culprit. Next to that is failed fasteners on top of the pack, usually from AC condensate, rain, or road salt infused moisture. Road salt areas tend to really accelerate this type of failure on older cars, too. I feel kinda bad for anyone up north who's driven regularly with a pre-2015 S in winter conditions.

We're working on custom replacement side vents (prototypes should be ready soon), but it's probably too little too late for a lot of folks.

Few sense wires were loose and some capacitors in bms boards had failed. Capacitors have been replaced, sense wires reattached.

Granted it's possible there's still something else, but for now all modules are balanced. Well if you're not willing to help, I'll have to find someone else.

Took a look on my car... can see why moisture ingress on side vents are rampant. Following pics are from my 6k mi/year car garage parked at home and work with no salted roads In rainy/wet PNW.

[...]

Since water and electricity don't mix, I'd imagine all EVs with battery pack on bottom of the car faces some challenging moisture ingress issues. Toyota hybrids don't have this issue because they tuck the small battery (compared to EV) in the center rear of the car above the floor board in away from any water under the hood/tire area.

... The 057 Tech Battery Monitoring Device that goes along with our extended service plans tries to gather more of the picture and come up with a better overall health estimate for the cell groups and pack as a whole by using some proprietary methods for coaxing more information than normal from the BMS. The vast majority of packs are perfectly fine, even with some voltage imbalance, as long as its within the limits of the BMS. It's the trends on this that tend to matter. If things are trending towards being outside the BMS's abilities, then this would be an issue. Most all batteries are trending this way, but at different rates. Some at a rate where issues won't occur for decades, others are a rate where you're going to be stuck in a few months or less. (We're actually considering exposing an estimated date range for this on the BMD dashboard for customers once enough data is collected to assess the trends.) There's just no way to really know based on passive CAN monitoring of group voltages alone.

It's not as much anything to do with a lack of willingness to help as it is with this being a self correcting error/alert. If the pack is actually fixed, the error will go away on its own after some use and the BMS recognizes the hardware fix. If it's not actually fixed, the error won't go away. There's only a handful of things that need manual resets on modern firmwares, and this isn't one of them.

We're still working through some hardware iterations needed to catch up completely with everyone else, so won't happen until that's completed. We have a handful of people who have been waiting quite a while for the units, unfortunately.Any news on the monitoring only BMD plan for us overseas classic S owners that are curious about their battery's well-being?

Had a guy from Ukraine help us out, he managed to reset the alert with a remote connection, once I had the tokens to the car. Everything seems to be in order now. We'll see if it lasts, customer knows that nothing is for certain and is comfortable with it.

Ukrainian fellow was of the opinion that "charge level reduced" alert used to be selfcorrecting, but is not anymore in latest softwares.

this is awesome. this sounds like an OK price for this.Tesla just replaced the HV battery in my 2013 P85+ with 308,402 miles on it. They installed a 90kw pack, new 12v battery, upgraded rear control arms and did a four wheel alignment for $15,500. When the car was new I got 265 miles of range. Now it gets 298 miles of range.

this is annoying that they try to hinder an effort just to keep old cars on the road. I guess it makes sense, since it might prevent one or two of us from breaking down and buying a new Tesla instead of trying to keep our current ones off the junk heap.Funny enough, it seems Tesla really doesn't like us gathering this data from customer vehicles and exposing it for them. We know for sure that Tesla themselves has at least one of our BMDs, and they've actually released a BMS OTA for some older S's somewhat recently that appears to have the sole purpose of obfuscating some of this data and the method we were using to gather it. Fortunately, the S/X BMS is an open book to me nowadays, so tracking these changes and updating the BMDs accordingly isn't a huge issue and there's not much they can do long term on this without hardware changes to older cars (not happening)

I'm interested. even though my car/battery is old, it will probably help.We're working on custom replacement side vents (prototypes should be ready soon), but it's probably too little too late for a lot of folks.