That's a nice looking setup!I splurged on MountainPass Performance's "Easy Big Fella" 400mm front rotors and the corresponding rotors for the rear, then went with Unplugged Performance's street/track pads for the stock calipers, and their stainless brake lines. Install was done by Parts3Xpress.com in Temple City, CA. I really smoked the OEM brakes at Willow Springs on drag nights when trying to slow down enough to make the return road. It's easy to see braking performance is a lot better just by driving around on streets. Thanks to everyone for the great products, and to P3XP for their excellent install work.Wheels are 20" forged Signature SV-501s. Next up: red calipers and (probably) metallic silver racing stripes. Woohoo! See you at Willow on drag nights.

View attachment 936390

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Model S Plaid Brakes Are Terrible!

- Thread starter theslimshadyist

- Start date

Gninoked

Member

Just completed the One Lap this past weekend and wanted to share some additional data to show how the MPP rotors, GLoc pads, and our prototype ducts/backing plates are now working.

Background - we have been doing some testing to see if we can increase the power over time the car can produce by increasing the cooling capacity of the car. The short answer is yes it does work, but I'll save that for a different thread. That's relevant because as we increase the power over time - we also increase the load on the brakes. More power for longer = more stops from higher speeds. This is why we decided to produce the prototype backing plate/duct setup I detailed in the other post, because we know we were relatively close to the limit of the existing setup and because we were seeing peak temps continue to increase even as the car ran out of power over time.

Measurement - Sasha and Mountain Pass Performance have setup this car to run brake temp sensors wired to a Motec for datalogging purposes. He also did some custom coding so that we can see the temperatures live on the screen in the Tesla software - his race and electronics engineering skill is unparalleled! This setup allows us to keep tabs on track, but also to review and test adjustments and do comparisons afterward. Rest assured that he does this sort of engineering/testing on all the MPP parts!

Results - This data comes from Hallett last week on a ~80 degree ambient day. The track is a ~2mile setup with lots of medium straights with big braking zones and a few medium speed corners with short braking zones. The OLOA format is 3 timed laps, all count, with 3/4 of a lap of warm up. For the Plaid, the goal is to get the tires and brakes up to temp (~120C ideally) without using much energy or heat capacity in the warm up. Because of the changes to cooling we were able to run this track with nearly 100% power when properly cooled before starting.

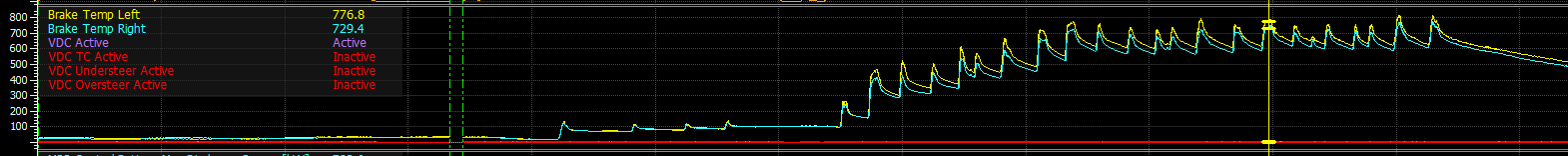

You can see here that the brakes came up to temp fairly quickly on the first lap before leveling off. The peaks during braking for laps 2-3 were all within ~50C of each other, mostly centered on 775C (think of this as the surface temp of the rotor) and then the temps decline quickly to ~675C (think of this as the core temp of the rotor.)

Here's an example from before the changes at Barber last year:

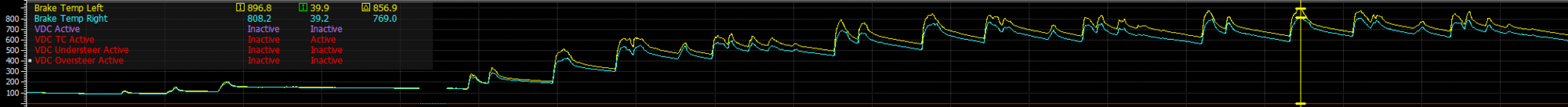

Each successive braking event is causing the peaks to go up 10-25C, and the peak right as we run out of power is just under 900C! Also remember this session the car was running considerably less power (50-100hp) at peak and at higher speeds (100-200hp.)

Short version - these ducts are doing the job. We are thinking about potential improvements and optimizations - if you have ideas let us know! We'd consider manufacturing and selling them at some point.

Background - we have been doing some testing to see if we can increase the power over time the car can produce by increasing the cooling capacity of the car. The short answer is yes it does work, but I'll save that for a different thread. That's relevant because as we increase the power over time - we also increase the load on the brakes. More power for longer = more stops from higher speeds. This is why we decided to produce the prototype backing plate/duct setup I detailed in the other post, because we know we were relatively close to the limit of the existing setup and because we were seeing peak temps continue to increase even as the car ran out of power over time.

Measurement - Sasha and Mountain Pass Performance have setup this car to run brake temp sensors wired to a Motec for datalogging purposes. He also did some custom coding so that we can see the temperatures live on the screen in the Tesla software - his race and electronics engineering skill is unparalleled! This setup allows us to keep tabs on track, but also to review and test adjustments and do comparisons afterward. Rest assured that he does this sort of engineering/testing on all the MPP parts!

Results - This data comes from Hallett last week on a ~80 degree ambient day. The track is a ~2mile setup with lots of medium straights with big braking zones and a few medium speed corners with short braking zones. The OLOA format is 3 timed laps, all count, with 3/4 of a lap of warm up. For the Plaid, the goal is to get the tires and brakes up to temp (~120C ideally) without using much energy or heat capacity in the warm up. Because of the changes to cooling we were able to run this track with nearly 100% power when properly cooled before starting.

You can see here that the brakes came up to temp fairly quickly on the first lap before leveling off. The peaks during braking for laps 2-3 were all within ~50C of each other, mostly centered on 775C (think of this as the surface temp of the rotor) and then the temps decline quickly to ~675C (think of this as the core temp of the rotor.)

Here's an example from before the changes at Barber last year:

Each successive braking event is causing the peaks to go up 10-25C, and the peak right as we run out of power is just under 900C! Also remember this session the car was running considerably less power (50-100hp) at peak and at higher speeds (100-200hp.)

Short version - these ducts are doing the job. We are thinking about potential improvements and optimizations - if you have ideas let us know! We'd consider manufacturing and selling them at some point.

Just completed the One Lap this past weekend and wanted to share some additional data to show how the MPP rotors, GLoc pads, and our prototype ducts/backing plates are now working.

Background - we have been doing some testing to see if we can increase the power over time the car can produce by increasing the cooling capacity of the car. The short answer is yes it does work, but I'll save that for a different thread. That's relevant because as we increase the power over time - we also increase the load on the brakes. More power for longer = more stops from higher speeds. This is why we decided to produce the prototype backing plate/duct setup I detailed in the other post, because we know we were relatively close to the limit of the existing setup and because we were seeing peak temps continue to increase even as the car ran out of power over time.

Measurement - Sasha and Mountain Pass Performance have setup this car to run brake temp sensors wired to a Motec for datalogging purposes. He also did some custom coding so that we can see the temperatures live on the screen in the Tesla software - his race and electronics engineering skill is unparalleled! This setup allows us to keep tabs on track, but also to review and test adjustments and do comparisons afterward. Rest assured that he does this sort of engineering/testing on all the MPP parts!

Results - This data comes from Hallett last week on a ~80 degree ambient day. The track is a ~2mile setup with lots of medium straights with big braking zones and a few medium speed corners with short braking zones. The OLOA format is 3 timed laps, all count, with 3/4 of a lap of warm up. For the Plaid, the goal is to get the tires and brakes up to temp (~120C ideally) without using much energy or heat capacity in the warm up. Because of the changes to cooling we were able to run this track with nearly 100% power when properly cooled before starting.

View attachment 938642

You can see here that the brakes came up to temp fairly quickly on the first lap before leveling off. The peaks during braking for laps 2-3 were all within ~50C of each other, mostly centered on 775C (think of this as the surface temp of the rotor) and then the temps decline quickly to ~675C (think of this as the core temp of the rotor.)

Here's an example from before the changes at Barber last year:

View attachment 938643

Each successive braking event is causing the peaks to go up 10-25C, and the peak right as we run out of power is just under 900C! Also remember this session the car was running considerably less power (50-100hp) at peak and at higher speeds (100-200hp.)

Short version - these ducts are doing the job. We are thinking about potential improvements and optimizations - if you have ideas let us know! We'd consider manufacturing and selling them at some point.

Do you think it would be a good idea to implement a downspout or catch can kind of device closer to the rotor, so that rocks and rubber/tire debris getting pulled into the intake would have a place to collect or fall out instead of getting funneled into the rotor?

Gninoked

Member

Maybe it wasn't obvious in the pics - the hexagonal openings in the screen on the ducts are about 1/4" across. Anything that can get through there can pass right through the rotor. That said it does make sense to pull everything apart and inspect/clean them from time to time!Do you think it would be a good idea to implement a downspout or catch can kind of device closer to the rotor, so that rocks and rubber/tire debris getting pulled into the intake would have a place to collect or fall out instead of getting funneled into the rotor?

dance.parrot

Member

I wonder if it will be possible to buy the brake calipers that come with the Carbon Ceramic from Tesla, and get iron discs and pads from a third-party, such as MountainPass.

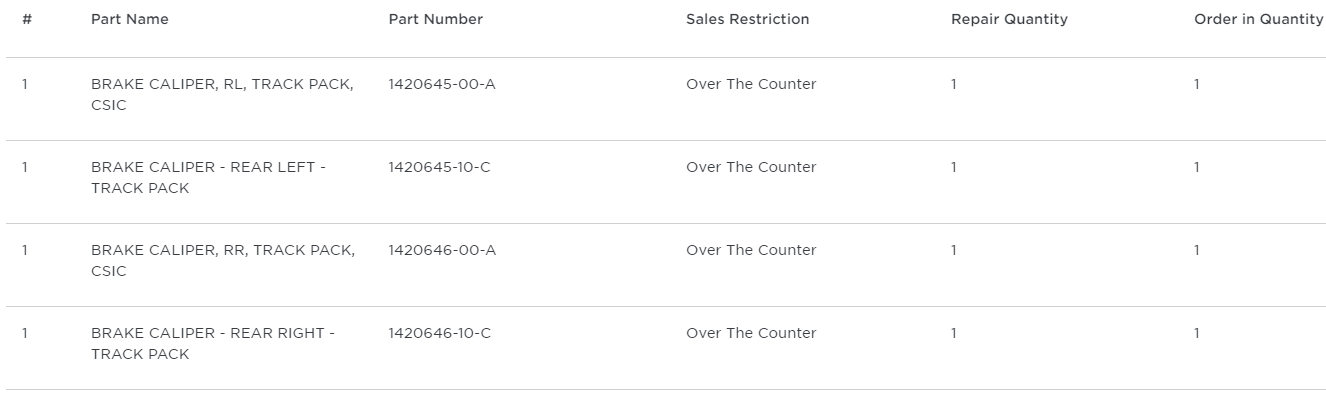

The Tesla Parts Catalog shows 4 rear TRACK PACK calipers (presumably 2 for the main brake, and 2 for the parking brake) available over the counter.

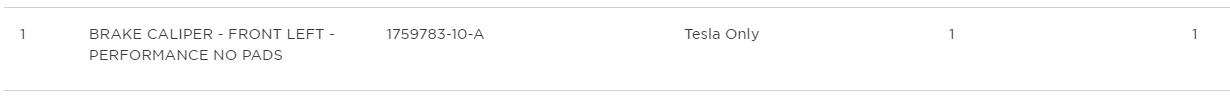

However, for the fronts, I only see a front-left, with a Tesla Only sales restriction.

The Tesla Parts Catalog shows 4 rear TRACK PACK calipers (presumably 2 for the main brake, and 2 for the parking brake) available over the counter.

However, for the fronts, I only see a front-left, with a Tesla Only sales restriction.

Another option is the Brembo GTS big brake kit.I wonder if it will be possible to buy the brake calipers that come with the Carbon Ceramic from Tesla, and get iron discs and pads from a third-party, such as MountainPass.

The Tesla Parts Catalog shows 4 rear TRACK PACK calipers (presumably 2 for the main brake, and 2 for the parking brake) available over the counter.

View attachment 940357

However, for the fronts, I only see a front-left, with a Tesla Only sales restriction.

View attachment 940358

I had one installed for fronts a few weeks ago and loving it. Comes with 6 piston Brembo GTS front calipers, 405mm iron discs and stainless steel lines. Was just a tad over $5k for all.

lbowroom

Plaid, white on black, CF, 8/27/21, Track Pack

I think the Tesla front rotors are 410mm so the calipers would be spaced accordingly. MPP big fellas are 400. I can see spacing up, but not down for calipers. Even worse for the rears, MPP are stock diameter.I wonder if it will be possible to buy the brake calipers that come with the Carbon Ceramic from Tesla, and get iron discs and pads from a third-party, such as MountainPass.

The Tesla Parts Catalog shows 4 rear TRACK PACK calipers (presumably 2 for the main brake, and 2 for the parking brake) available over the counter.

View attachment 940357

However, for the fronts, I only see a front-left, with a Tesla Only sales restriction.

View attachment 940358

dance.parrot

Member

Can you share a link to the kit/pads? Do you need an adapter to mount the caliper?Another option is the Brembo GTS big brake kit.

I had one installed for fronts a few weeks ago and loving it. Comes with 6 piston Brembo GTS front calipers, 405mm iron discs and stainless steel lines. Was just a tad over $5k for all.

Did you do anything to the rears?

dance.parrot

Member

You'd definitely need different rotors. I was wishfully thinking that MPP could use their existing hats on larger and thicker Girodisc rotors.I think the Tesla front rotors are 410mm so the calipers would be spaced accordingly. MPP big fellas are 400. I can see spacing up, but not down for calipers. Even worse for the rears, MPP are stock diameter.

Tsport line also sells the Brembo kit, but they don’t have the GTS kit, only the GT. I think my shop got the GTS kit straight from Brembo. Here is a link for Tsport line so you can see everything that comes with it.Can you share a link to the kit/pads? Do you need an adapter to mount the caliper?

Did you do anything to the rears?

Brembo Gran Turismo Tesla Model S / X Plaid & Long Range Big Brake Kits

T Sportline has mated their Tesla expertise with the market-leading braking expertise from World-renowned racing brake experts, Brembo. The Brembo Gran Turismo Tesla Model S Plaid & Long Range Big Brake Kits have been exhaustively tested and validated by T Sportline to ensure proper quality...

For rears, I’m using MPP rotors (same diameter as stock), stock calipers, but upgraded pads and stainless lines.

Here is a pic of mine with Signature 20” wheels

Attachments

Tiger

Active Member

MichaelP90DL

Active Member

Awiner

Member

You are at the point to flush. If you are really heating it up on the track flush after every track day. For street use every year at the maximum is suggested.How often is the Motul RBF 660 brake fluid supposed to be changed? I am right at 12 months with two track days and I was just going to buy a new bottle and bleed the brakes but I keep finding conflicting info. Thanks.

By that point, especially in a humid environment, the fluid will have absorbed a significant amount of water and the “wet” boiling point will be a more accurate representation of the performance you can expect.

Last edited:

juanmedina

Active Member

You are at the point to flush. If you are really heating it up on the track flush after every track day. For street use every year at the maximum is suggested.

By that point, especially in a humid environment, the fluid will have absorbed a significant amount of water and the “wet” boiling point will be a more accurate representation of the performance you can expect.

Does the Endless RF650 brake fluid last longer? Someone recommended this one with a 3 year life:

DOT 4 TYP 200 Brake Fluid (1 Liter) - ATE BF1200

Awiner

Member

Endless RF650 supposedly absorbs water at a lower rate which would extend the service life. Maybe 2 years between flushes would be safe (unless you track it).Does the Endless RF650 brake fluid last longer? Someone recommended this one with a 3 year life:

DOT 4 TYP 200 Brake Fluid (1 Liter) - ATE BF1200

MFrunkerOG

Active Member

It’s been 2 months since I replaced the street pads with aggressive Gloc R12 pads. Those were initially put on for a day at the track, but I kept procrastinating on going back to the street pads after.

Braking performance has been good at ambient temps and just gets better when they’re hot so no reason to switch back at least as long as it doesn’t get under 40F. I’m going to leave the aggressive pads on until I switch to all season tires in the fall.

Braking performance has been good at ambient temps and just gets better when they’re hot so no reason to switch back at least as long as it doesn’t get under 40F. I’m going to leave the aggressive pads on until I switch to all season tires in the fall.

Just came across this thread which really gets going starting with this post from @Knightshade This thread is worth skimming for many of the issues discussed here.

teslamotorsclub.com

teslamotorsclub.com

Concerns over Model 3 Performance brakes efficiency. How good is it? After market brakes?

Hi I had a great opportunity to buy a brand-new model 3 performance from someone else. Apparently, he needs that money for his business. The car is arriving mid-late next month. Despite ordering the Performance model, I’ve never driven it. I’ve ridden in it. It was amazingly quick as my head...

Last edited:

MFrunkerOG

Active Member

I think they argue just like usJust came across this thread which really gets going starting with this post from @Knightshade This thread is worth skimming for many of the issues discussed here.

Concerns over Model 3 Performance brakes efficiency. How good is it? After market brakes?

Hi I had a great opportunity to buy a brand-new model 3 performance from someone else. Apparently, he needs that money for his business. The car is arriving mid-late next month. Despite ordering the Performance model, I’ve never driven it. I’ve ridden in it. It was amazingly quick as my head...teslamotorsclub.com

Similar threads

- Replies

- 13

- Views

- 651

- Replies

- 7

- Views

- 638

- Replies

- 203

- Views

- 12K