Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla, TSLA & the Investment World: the Perpetual Investors' Roundtable

- Thread starter AudubonB

- Start date

I just don't think the cost/benefit ratio is there for passenger cars. The hydraulic disc brakes don't heat up to the same extent under normal operating conditions since there's an order of magnitude less weight to decelerate.

The discussion went down the path the issues of cold-soaked batteries and/or high SOC limiting regen capability, and methods to address that, including resistive load banks. My suggested solution improves on that idea by using the heat by-product to heat the cold pack, rather than the outside air, reducing the time it takes before you can once again recover the energy from regen, something that's even more useful on semi's.

Nobody was speaking to cost/benefit that I could see, and I certainly wasn't. Just potential technical solutions. But since you brought it up, and suggested it's not feasible, what are your cost estimates for producing such a system at scale?

One option if the expense doesn't make sense for all cars, would be part of a cold weather package. The availability of such might make more sense for the semi.

Just incase I wasn't clear about why Lucid and Rivian are terrible investments and are so far away from profitability, MeetKevin today breaks down the math and compares it to Tesla's early years.

The discussion went down the path the issues of cold-soaked batteries and/or high SOC limiting regen capability, and methods to address that, including resistive load banks. My suggested solution improves on that idea by using the heat by-product to heat the cold pack, rather than the outside air, reducing the time it takes before you can once again recover the energy from regen, something that's even more useful on semi's.

Nobody was speaking to cost/benefit that I could see, and I certainly wasn't. Just potential technical solutions. But since you brought it up, and suggested it's not feasible, what are your cost estimates for producing such a system at scale?

One option if the expense doesn't make sense for all cars, would be part of a cold weather package. The availability of such might make more sense for the semi.

Anything is feasible. But the best part is no part, yes? There's a very strong likelihood that rheostatic braking is completely unnecessary for the Semi, let alone 3,Y,S, &X. I liked the idea initially too, but it's probably a solution in search of a problem.

thesmokingman

Active Member

Man, when put into a spreadsheet like that, it's not even close.The weekend isn't over yet right? This EV Semi comparison was posted recently

View attachment 881583

long essay on Tesla Semi, a deep dive

The real question is, how did a driveway paver from Nikola managed an engineering team that produced a decent efficient truck?The weekend isn't over yet right? This EV Semi comparison was posted recently

View attachment 881583

long essay on Tesla Semi, a deep dive

StealthP3D

Well-Known Member

It was regarding the mining process of silicium in China, where child labor allegedly is pretty common. Hard to tell if it is true, but never the less a dramatic picture to paint…

Tell them they are just trying to "virtue signal" by not using solar panels! /s

The real question is, how did a driveway paver from Nikola managed an engineering team that produced a decent efficient truck?

I'd turn that question around and ask, why are the other truck development teams so bad that they were beaten by a driveway paver? There are plenty of smart shade-tree mechanics after all.

So… two weeks maybe?

ThisStockGood

Still cruising my Model S 70 2015

Closed loop on the factory because covid?

Line upgrades?

The elephant in the room is that the wave will die out naturally as the Berlin and Texas gigafactories ramp up. Take for instance Europe (the biggest cause of the wave because all Tesla’s for Europe had to be shipped by ship for weeks, until Berlin production is ramped): With Berlin reaching 5000/week production, that’s 65K per quarter. Q3 had 50K sales in Europe. The cheapest Model Y is cheaper than the cheapest Model 3 in Europe, so pricewise Europeans will tend to buy the locally produced Model Y’s instead of Model 3. The wave to Europe will only be for the less popular Model 3/S/X. No doubt something similar will happen with the production in Texas.I still think Tesla does some exporting in December. But nothing like what Troy has been pushing as a narrative. Maybe they increase the vehicles in transit from 20k to 30k. Or maybe they keep the 20k in transit steady from Q3 to Q4. Just because there are no ships on schedule right now doesn’t mean there won’t be any in a week or two.

Most of it, to be honest. There’s a small amount of wastage but it’s mostly reusable. The industry is so huge, however, that it accounts for nearly half of all cobalt production.Same line of thought: I always ask what percentage of the cobalt (dug up by the same child labour that is always brought up in these conversations) that is used as a catalyst for the creation of low sulphur diesel, is recycled.

Tesla Daily: Tesla News & Analysis: Semi Battery, Charging, & Delivery Details + China Update (12.02.22)

Starting: 00:10:12

https://traffic.libsyn.com/secure/t...hina_Update_12.02.22.mp3?dest-id=561941#t=612

Might be demand issue

Todesbuckler

Member

Should be wholesale MIC (export + retail sales).

Great numbers and a new record!

Attachments

What do you mean logic? November and December are not the same month. These are 2 different things completely.

Tesla Falls on Plan to Cut Output of EVs at Shanghai Factory

Tesla Inc. plans to lower production at its Shanghai factory, according to people familiar with the matter, in the latest sign demand in China isn’t meeting expectations. The company’s shares fell in early trading.

Tesla Falls on Plan to Cut Output of EVs at Shanghai Factory

Tesla Inc. plans to lower production at its Shanghai factory, according to people familiar with the matter, in the latest sign demand in China isn’t meeting expectations. The company’s shares fell in early trading.www.bloomberg.com

Please don't repost things that have already been posted very clearly at the top of the page you're posting on. Just because the link you posted is from Bloom "people familiar with the matter" berg and adds any predictable negative slant they can doesn't mean it's a different story.

Last edited:

What do you mean logic? November and December are not the same month. These are 2 different things completely.

What are the chances of a demand problem December article with a super FUDdy title dropping at the same time as the expected release of record-setting November numbers?

UkNorthampton

TSLA - 12+ startups in 1

I haven't caught up yet, did do a search though and can't see it posted

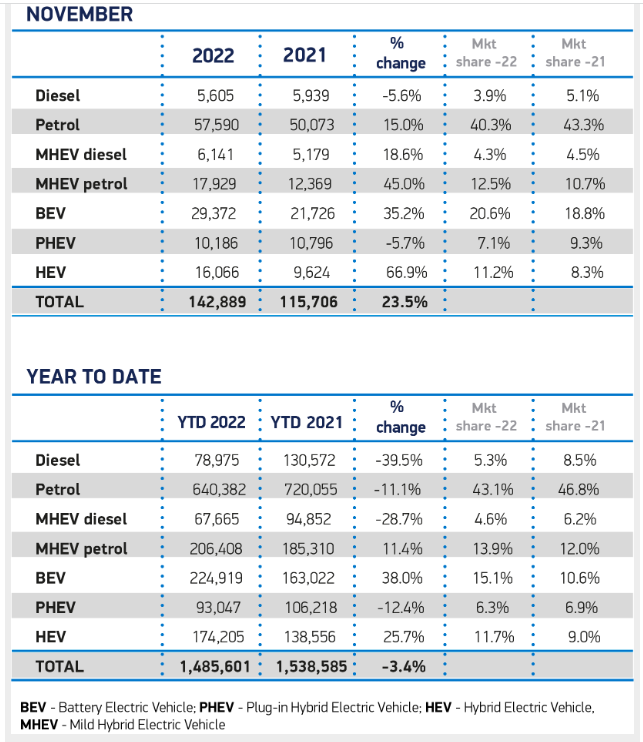

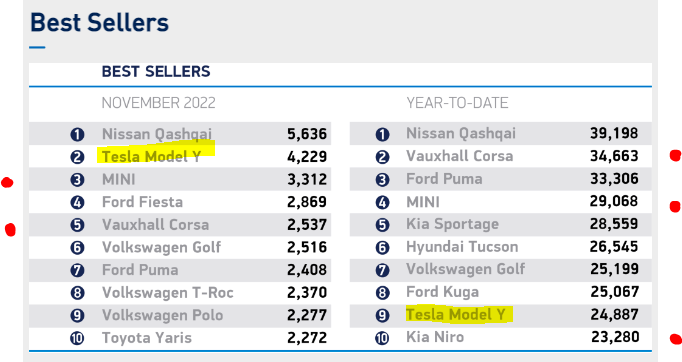

UK / SMMT - Battery Electric Vehicles passed 20% in November 2022

Tesla at 4.22% of all cars irrespective of powertrain

www.smmt.co.uk

www.smmt.co.uk

Car Registrations (brand tab)

Edit: Best sellers - Model Y at 2nd for November. Red indicates some electric models, but not all electric.

UK / SMMT - Battery Electric Vehicles passed 20% in November 2022

Tesla at 4.22% of all cars irrespective of powertrain

Car Registrations

SMMT is the country’s primary source of data on the motor industry. Click here for the SMMT car registrations data published monthly

Car Registrations (brand tab)

Edit: Best sellers - Model Y at 2nd for November. Red indicates some electric models, but not all electric.

Attachments

Last edited:

Similar threads

- Locked

- Replies

- 0

- Views

- 3K

- Locked

- Replies

- 0

- Views

- 6K

- Replies

- 6

- Views

- 5K

- Replies

- 6

- Views

- 11K

- Locked

- Replies

- 27K

- Views

- 3M