The Extent of Tesla's Battery Advantage

Warning: Link Barrage

I have been doing some research on this recently, including going through old posts. The best and most relevant threads by far are the ones by CapitalistOppressor. Here are two very good ones:

Model S Battery Pack - Cost Per kWh Estimate

Amazing Core Tesla Battery IP - 18650 Cell

Essentially, I think Tesla has an advantage on many levels. Tesla has over 100 patents on batteries on the cell, module, and pack levels. The four fundamental areas in which Tesla has an advantage are: Charging Rate, Battery Life/Safety, Energy Density, and Cost.

Charging

Some of Tesla's Supercharging stations can charge at 135kw by bypassing the 10kw or 20kw dual chargers onboard. Meanwhile, most other electric cars have either 3.3kw or 6.6kw onboard chargers, and most "fast chargers" for these cars are around 24 kw. CHADEMO is capable of 62.5kw, but no car other than Tesla can handle that rate AFAIK

(EDIT: the Kia Soul EV can apparently handle the 62.5kw rate of CHADEMO). Clearly, Tesla's charging rate is much faster than any other electric car. There are a few good reasons for this, the main one being that a larger battery can charge faster than a smaller battery because it can take more power. The other reason Tesla has achieved such a high charge rate is with an optimized BMS (battery management system) which is capable of controlling voltage to each cell.

Tesla has some very good Intellectual Property for their charging:

-

Charge Rate Optimization Patent

-

Low Temperature Fast Charge Patent

-

Charging Efficiency Using Variable Isolation Patent

-

Fast Charging of Battery Using Adjustable Voltage Control Patent

-

Battery Charging Time Optimization System

Also,

JB Straubel wants to get the charge time for the Model S down to 5-10 minutes.

Battery Life/Safety

Tesla has achieved very good battery life as well.

Here is some proof of the claim that Tesla has excellent battery life:

This is data from the Dutch and Belgian forums. LINK

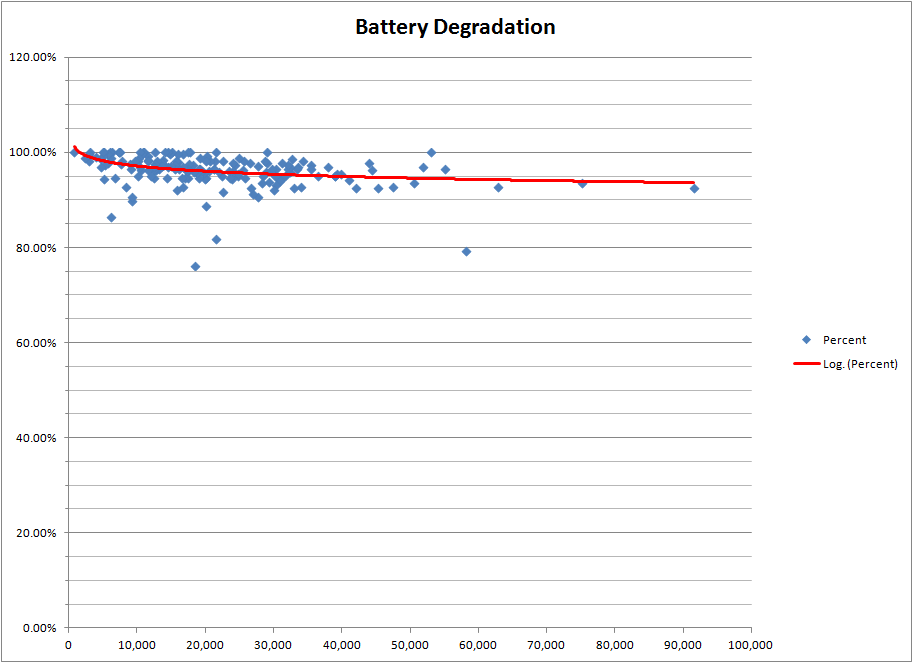

This is data from the Plug In America survey for Model S battery degradation, I made the graph (excludes some data with cars over 265 miles of range). LINK

Also, here is some battery reports from the Roadster and Nissan Leaf from Plug In America.

Roadster Battery Degradation Report

Nissan Leaf Battery Degradation Report

Having a larger battery also helps here, since charging and discharging a 100 mile range car to cover 100,000 miles would take 1,000 cycles, while charging and discharging a 250 mile range car to cover 100,000 miles will only take 400 cycles. Therefore, a longer range car (due to a larger battery) will be able to achieve longer battery life. And again, Tesla's technology within the BMS (battery management system) and the design of the pack only helps. For example, Tesla was really paying attention to good thermal management with their cells, and they have incorporated module level thermal management material, intumescent goo to resist thermal runway, and even a battery coolant sleeve/jacket. Here is Tesla's related IP:

-

Cell Thermal Runway Propagation Resistance Using Dual Intumescent Material Layers

-

Method Of Controlling System Temperature To Extend Battery Pack Life

-Method And Apparatus For Extending Lifetime Of Stationary Energy Storage Devices

-Battery Module With Integrated Thermal Management System

-

Battery Pack Directed Venting System

-Detection of Overcurrent In Battery Pack

Energy Density

Tesla achieved higher energy density and lower cost for their batteries by radically simplifying the battery cell. Since Tesla planned on stuffing a huge amount of these battery cells into a battery pack, it would be redundant and unnecessary to implement safety systems that can instead be implemented on a pack or module level, so they radically simplified the cell itself and moved the safety systems (including exterior insulation) to the module and pack levels. This makes the battery higher energy density, and makes the cells easier and cheaper to manufacture. Here is a diagram of a typical 18650 battery cell (Left) versus Tesla's simplified cell (Right).

The patent for this cell-

"Cell Cap Assembly With Recessed Terminal and Enlarged Insulating Gasket"

So how much did this help with Energy Density on the pack level? It turns out a lot, because Tesla is the absolute leader on energy density. Here is my data and chart from the Long Term Thread:

Data

Chart (

Red is 100% Tesla cars, orange is Tesla inside, and green is non-Tesla vehicles)

Sources:

The next best battery pack in terms of energy density is on the Mercedes SLS AMG Electric Drive (which costs $435,000). Its energy density is 30% lower than what Tesla had in 2012 and 40% lower than the recently upgraded Roadster. Also, Tesla's energy density seems to be improving at a steady rate of about 4.7% per year.

Battery Cost

Tesla has the lowest battery cost in the electric car industry currently, the only question is how much lower are Tesla's costs. Estimates range from $200-$300 for Tesla's battery pack, and they range from $160-$200 for Tesla's cells. Here are some sources for estimated battery costs:

-Lux Research estimates $274/kWh for the battery pack

-Navigant Research estimates that Tesla pays $180/kWh for their battery cells

-JB Straubel - Battery costs less than 1/4 of the price of the car (August 2013)

-Anderman Tesla Battery Report estimates $221/kWh cells in 2013, $172/kWh cells and $220-$260/kWh for the battery pack

Based on these sources, I believe that it is reasonable to narrow down Tesla's current costs to $240-$275/kWh for the battery pack. I come up with the low end of that range by taking the $180/kWh cell level estimate and assuming that it is 75% of the cost of the battery pack. For the high end, I am using a mix of estimates. In August 2013, as JB Straubel stated, the battery costs 1/4ths of the car's sale price. The Model S starts at $71,070, and 1/4th of that is $17,767.5 for the 60 kWh battery pack, which is $296.125/kWh. Assuming this has declined at about 5% over the last year and a half (which is conservative, since the estimated improvement every year in energy density and/or cost is 7%), the current price would be about $274/kWh, which is in line with Lux Research and Anderman's projected cost of $260/kWh in 2016 for the high end.

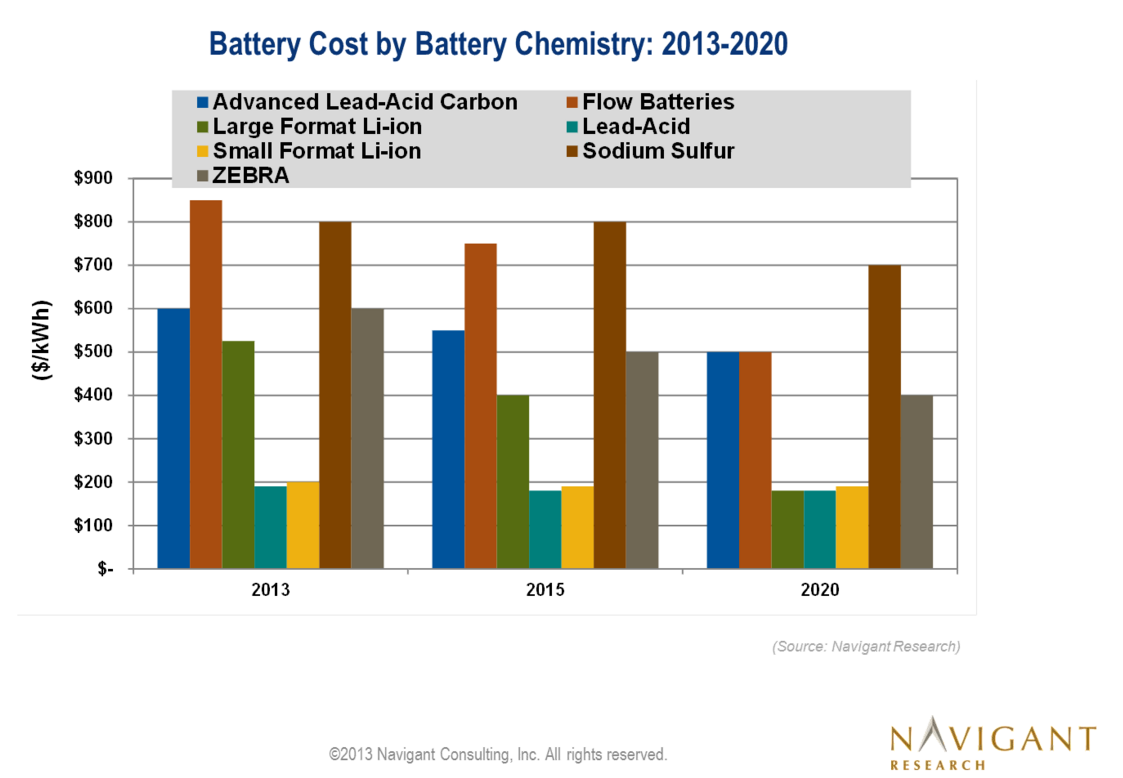

Here is Navigant's estimates for other electric car batteries (2013 estimates and 2015 projections look good, but I would take the 2020 projection with a HUGE grain of salt):

Essentially, Tesla has a battery pack cost of about $240-$275/kWh, and competitors who use large format lithium ion batteries have a cost of about $400/kWh currently, which puts Tesla in the lead by more than 30%.

Conclusion

To insult or joke about Tesla's batteries (something Tesla bears love to do) is absolutely silly. Also, its silly to believe that Tesla's batteries is all Panasonic. Tesla, together with Panasonic is undoubtedly the leader in EV batteries currently on multiple parameters. Tesla is trying to stay ahead by building the Gigafactory, planning on manufacturing a larger cell, continuing to invest in batteries (especially stationary storage), and adding to their patent portfolio (despite their open sourcing). At this point, even a breakthrough in battery technology that is exclusive to other auto manufacturers will not put them ahead of Tesla. It will take a significant amount of time before any other battery technology can beat Tesla's batteries on all of these various fields, especially since Tesla is moving the goal post at a very high speed. All I can say is, good luck to the other auto manufacturers.