Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla, TSLA & the Investment World: the Perpetual Investors' Roundtable

- Thread starter AudubonB

- Start date

StealthP3D

Well-Known Member

I am confident in two things:

1) anyone remotely curious and looking at the financials will quickly discover the COGS for the model 3 is remarkably high, and in line with all the claims I have made with little math required or little assumption required. It takes almost no time to investigate so I recommend you do it yourself.

2) that factchecking is one of the least competent and most diversionary members of this board specifically because he operates not from evidence to conclusion but the reverse almost every single time, not to mention his incredibly fast movement to conspiracy talk whenever threatened which is a low probability conclusion. I highly recommend both neroden (although I find flaws also), and doggydogworld (who so far seems pretty spotless).

Wondering where you have been since June 10th?

Depends on domain I suppose, but the correct address should be "Sir Elon" OR "Lord Musk". Then again, people say the strangest things.No advanced degrees. That was my point.

Question is, how long will it be before he is knighted and respectful people address him as "Sir Musk", LOL!

kengchang

Active Member

No, this has been covered multiple times in this threadAccounting question (probably already discussed; if so apologies for asking again):

Could Tesla have delivered a few Made in China M3 in late December in order to put some of the production costs in Q4? Knowing they had record deliveries with a wonderful mix of S+X and LR M3s, they may have decided to use some of that to partly cover for GF3 M3s and get an advantage for 2020 Q1 profits.

Does this make sense? Is it even possible?

StealthP3D

Well-Known Member

I am fighting tooth and nails to get my financial situation to match up to the percentage quartile that my IQ is in.

You are trying too hard. It's almost always better to do nothing. I'm being dead serious here.

WSJ - 17 minutes ago: New Charge in UAW Corruption Investigation Specifies Racketeering

Excerpt:

Federal prosecutors filed a new charge against a former United Auto Workers official Monday, alleging the defendant was involved in an embezzlement scheme that was part of a wider racketeering enterprise at the union.

Excerpt:

Federal prosecutors filed a new charge against a former United Auto Workers official Monday, alleging the defendant was involved in an embezzlement scheme that was part of a wider racketeering enterprise at the union.

I think GF3 production may unfold something like this during 2020:

This is a very cautious rampup schedule, which should enable Tesla China to transition from 30% local production now to 100% by end of 2020.

- Jan 1st-23rd: 1K/wk (1 shift, 5 days/wk + 1 day trg)

- Jan 24-Feb 8: New Year Festival shutdown

- Feb 9 - Mar 31: 2K/wk (2nd shift, 6 days/wk)

- Apr 1st - Jun 30: 3K/wk (locally src'd bty cells)

- Jul 1st - Sep 30: 4K/wk (cont'd rampup)

- Oct 1st - Dec 31: 5K/wk (cont'd rampup)

The final tally for 2020? 193K Model 3s produced. Gets big fast, don't it?

Best part is GF3 enters 2021 at 5K/wk Model 3

Just stop it. Tesla has said that the Model 3 capacity at GF3 is 150k/year or ~3k/week. They aren't going to ramp it to 5k/week.

And unless they have changed their minds the LR Model 3 will still be made in Fremont and imported. GF3 makes SR/SR+ only.

Animals: African Leopard, Beaver, Eagle (representing the three countries he's lived in)What would you put on Elon's armourial achievement if you were designing it? What supporting animals? What motto? What battle cry?

Motto: Si iustum est tenete

Battle cry: Perge ad Martis

Crest: Cybertruck

Helm: Frogmouth

Tincture: gules "T" on argent

Are you implying that it's not really dumb to purposefully create an information vacuum around your investments?

So that's one level of dumbness. But to look at a five year chart and not have covered back in the $300's takes "dumb" to a whole 'nother level! Maybe some other language has a word for this level of dumbness, but English is lacking here. Maybe the Russians have a word for this?

kaputski

It's a wait and see until someone from Tesla tells us or some customers start poking around after delivery.This may have already been asked and answered, but does anyone know if the 3's and the Y's being built in Shanghai will utilize the new wiring "harness?" What about here in Fremont? Inquiring minds want to know...

I don't think there is any certainty that they will be using a new wiring harness with 3 or Y. I recall the discussion stemming out of patent applications, but I don't think we have ever heard anything official. Patents don't necessarily equate to production.

What would you put on Elon's armourial achievement if you were designing it? What supporting animals? What motto? What battle cry?

(Pretty much OT. Sorry.)

Would be perfect, but a certain Scottish family might object:

'Orbis non sufficit'

JusRelax

Active Member

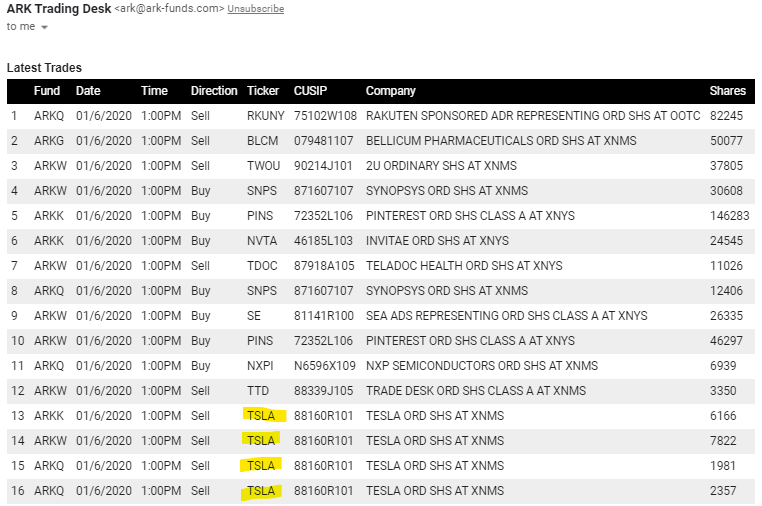

ARK did some light TSLA selling in a number of their funds today:

Not significant amount shares, but iinteresting that it was across multiple accounts this time.

Not significant amount shares, but iinteresting that it was across multiple accounts this time.

Krugerrand

Meow

i am friends with lots of millionaires through one hobby and lots of lowlife borderline hobos through another, and i can honestly say, if anything, in my experience the correlation between money and intelligence is negative if it exists at all.

And now I’m left wondering what sort of hobby a hobo might have — chess?

Thanks mate. Wish I could remember all the stuff I thought I heard or read, as the concept makes so much sense in reducing both production cost and time. I thought I remembered it stated it would be utilized in the Y and since there are a lot of similarities between the 3 and the Y it just seemed to make sense to implement it's use in both in the new GF3. But what the hell do I know except I can now buy new shoes and can't wait until tomorrow! Plus who would ever have thought Marshawn Lynch would be scoring TD's again for the Seahawks? Dreams can come true...It's a wait and see until someone from Tesla tells us or some customers start poking around after delivery.

I don't think there is any certainty that they will be using a new wiring harness with 3 or Y. I recall the discussion stemming out of patent applications, but I don't think we have ever heard anything official. Patents don't necessarily equate to production.

Last edited:

Carl Raymond

Active Member

Just stop it. Tesla has said that the Model 3 capacity at GF3 is 150k/year or ~3k/week. They aren't going to ramp it to 5k/week.

And unless they have changed their minds the LR Model 3 will still be made in Fremont and imported. GF3 makes SR/SR+ only.

I never believed that for a minute. If Fremont can do 7k/week, why would they design a brand new factory and cap it at 3k/week?

Setting expectations low.I never believed that for a minute. If Fremont can do 7k/week, why would they design a brand new factory and cap it at 3k/week?

SoGA Fan Club

Member

I think in last two years Elon earned a PHD from the school of hard knocks.No advanced degrees. That was my point.

Question is, how long will it be before he is knighted and respectful people address him as "Sir Elon", LOL!

(edited for correctness)

ARK did some light TSLA selling in a number of their funds today:

View attachment 497253

Not significant amount shares, but iinteresting that it was across multiple accounts this time.

They manage mutual funds (ETFs) and prudence requires that no one stock becomes too large a percentage of a particular fund. TSLA remains easily the largest holding in all three of those funds at more than 10%. Their rule is to not buy any more of a stock that exceeds 10% of a fund, and to perhaps pare some of it to purchase more shares of laggards.

ARK CEO Cathie Wood has said that TSLA is her highest conviction stock. Below is what she tweeted on Thursday.

I never believed that for a minute. If Fremont can do 7k/week, why would they design a brand new factory and cap it at 3k/week?

To keep cost and space utilization down since they don't expect to need to build that many Model 3s continuously for the particular service area. It seems that they are sizing each of the modules in GF4 similarly at ~3k/week. They may have figured out that that is the optimum rate for efficiency.

If they need another 3k/week they just build another mirror module.

Similar threads

- Locked

- Replies

- 0

- Views

- 3K

- Locked

- Replies

- 0

- Views

- 6K

- Replies

- 6

- Views

- 5K

- Replies

- 6

- Views

- 11K

- Locked

- Replies

- 27K

- Views

- 3M