ZenRockGarden

Active Member

Did he measure both an SR AWD and LR on the same scale?

Edit: Just found the video. So he's claiming after subtracting his weight and cargo, his Model Y measures at 4220 lbs. And he cites 4555 lbs as the MYLR weight. But on Tesla's website, the weight for the MYLR is listed as 4363 lbs or 4398 for the MYP. 140 lb difference is pretty decent, but probably can be explained entirely by the battery capacity difference

Yeah, I was following the different weight threads with interest too. Official weight is almost the same between MYAWD and MYLR. Then we have this one data-point which unfortunately is isolated and relies on both the accuracy of the particular scale and the assumptions for equating to official curb weight. A back-to-back on the same scale with a MYLR would have been vastly more interesting since I think he's got 100 pounds or more of assumptions in the exercise.

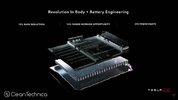

Bottom line for me is that so far, the MYAWD is not showing much weight savings from structural-battery-mega-cast yet.