Thanks for taking the time to go back through the conference call, I was mostly throwing the information out there so we can hopefully all stay on the same page on what we understand will be happening. Your main point was a good one, though, which is that regardless of how they ramp getting back to 1 month wait times is going to take a while.

The only thing to consider outside of that is if demand falls off some. I am not really too concerned about this, but it should be noted that with both the P85D and 85D coming out this likely boosted demand a bit more than it reasonably should be at this point. Even Elon mentioned as much with regard to the last Conference call he said current demand immediately following the D event was around 70k, but he was giving a more conservative number of 50k simply because he knew the number would come down some (although how much is unknown). It could also be that by the time demand does start to come down, the underlying demand levels (uninflated by the new products) will have caught up to a point where it tracks sideways for a bit.

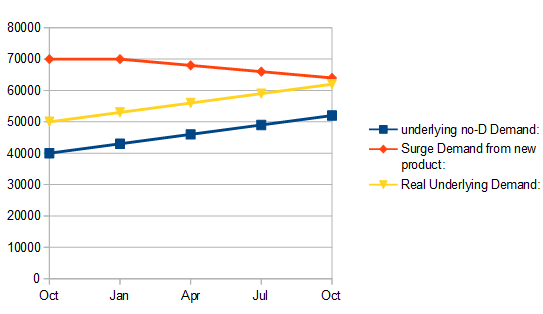

I hope this chart makes sense. These are just hypothetical numbers to show what I am getting at and in no way am I making a prediction here. This is also an extrapolated weekly order rate assuming it stayed flat, in the same way Elon threw out the 70k number. It might have been less confusing to show a chart that has a weekly intake rate of like 769 = 40,000 or 1346 = 70,000... but hopefully this makes sense.

Anyway, with this, the blue is the growth of the Model S demand based on No-D product being released... if they just kept on with the RWD only cars. I am just assuming a nice slow growth rate here. Then you have the surge of orders thanks to the new product release. I will assume that keeps up for a solid quarter before tapering back as demand is satisfied across both the P85D and the 85D as you have people in two categories here: Those who are upgrading from a previous model S and those who are otherwise new customers who were waiting for an AWD option (or some other recently added feature, like heated steering wheel or the autopilot stuff). Clearly as the surge of new customers tapers off, this number would come down.

Now the important number is the yellow real demand which includes the new feature set. This is an attempt to show a number that excludes the surge of customers, but includes the new addressable market (that is, those who wouldn't touch the model S unless it had those new features). This is the number of people who would be ordering the car (in my mind) as if Tesla had come out the gate in 2012 with these options available from the start.

So what you have here is the growth of real demand still rising (word of mouth, awareness, opening up to new markets, etc.) and the collapse of those who jumped on the "new" product... because... it's new. At some point the two lines meet and the Real Demand will take over. But the actual visible order rate we see (the red line) would appear that demand is falling off.

This is an important concept to understand, and what Elon was trying to get at on the lastest conference call. That demand is likely to fall back since right now the 70k order rate is not sustainable. How much it falls back and how that affects the wait times and the real demand is up in the air. Elon came in with the (assumed conservative) number of 50k real demand for 2015. The point is, our wait times could likely drop down as the surge dies off and the underlying demand gets reached.