C/P from evclinic:

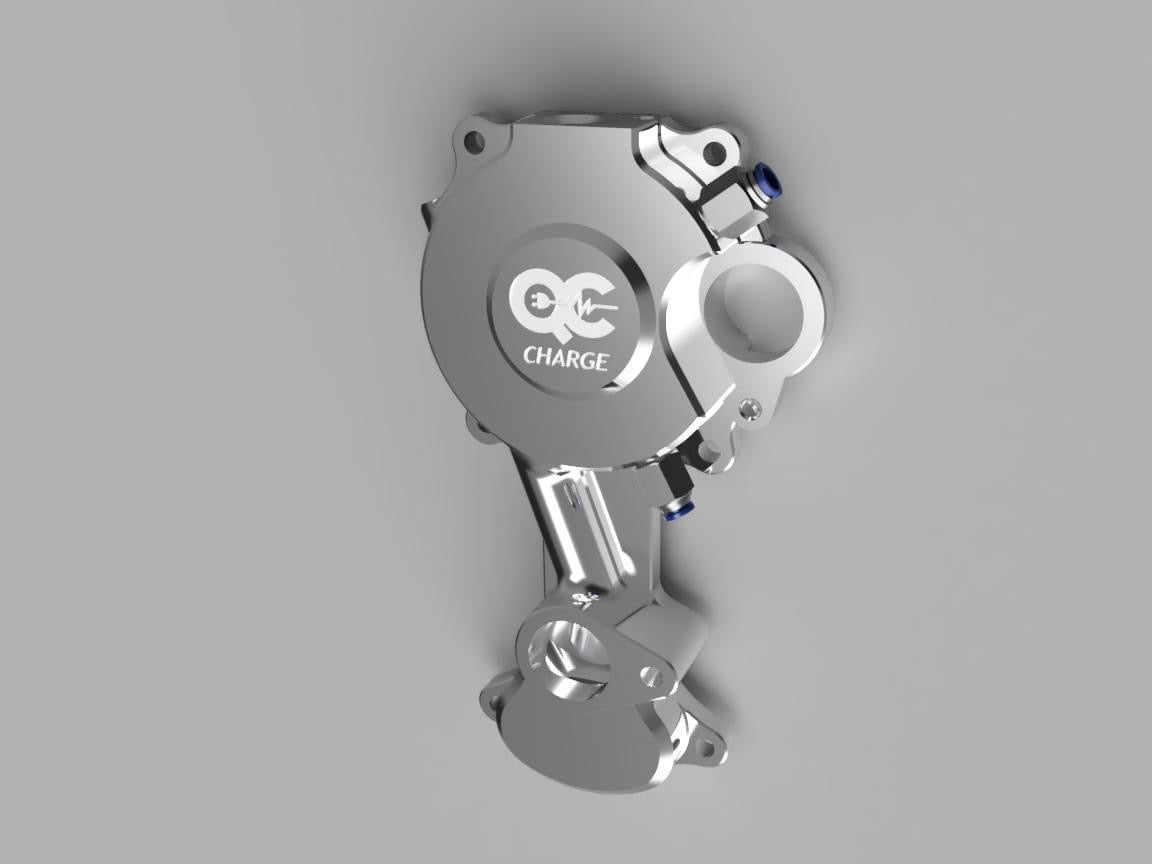

Our new coolant system cant ever ever again let coolant inside stator.

Our new stator cant ever ever get low isolation or overheating problems

Our new stator should increase range and power, decrease heating of the system

Our complete LDU assembly should last at least 700000km

If this is true, then its really good news. I want a P100D model, but untill now the fear of replacing LDU every xy K miles was a deal braker...

Do you think its true what the evclinic is saying and that even the LDU can be "fixed" properly?

My understanding is EV Clinic use triple lip seal. Currently I only know 1 triple lip PTFE seal supply for this LDU from small Chinese company via Aliexpress. Many DIYer worry poor quality from aliexpress seal. But from every LDU rebuild I have seen, they ALL use this seal. I can easily confirm from their pictures, videos etc. Personally I think there is no magic about PTFE seal, just need to have the right hardness blend (and the mating shaft surface MUST be properly prepared) Other big seal vendors such as SKF, Saint-Gobain, Parker have custom seal divisions but they seem to only focus on high volume OEM business. I doubt any small quantities are provided. But maybe EU with higher right to repair culture have other triple lip seal sources for small quantity for shops such as EV Clinic. Anyway, if I had to guess, I think EV Clinic use Aliexpress seal.

Finally, will a triple lip seal with properly finished rotor shaft surface last 700km? Personally I feel that is too optimistic. Seal and/or shaft will wear as I noted in above thread post depending on hardness of PTFE blend material and shaft metal alloy blend hardness. But I do believe EV Clinic so far shows the best rebuild process I have seen. Their video actually show carefully prepare the rotor shaft surface via chrome plating.

Almost all the longest lasting LDU we have seen are all early made factory original new LDUs. I'm guessing they last because 1) pristine new rotor shaft surface 2) triple lip PTFE seal. All the Tesla remans are single lip seal and what appears to be unrefinished rotor shaft seal surface. So if EV Clinic do good job on shaft surface preparation, maybe 300-400km is possible? We have heard some original LDUs lasting over 150k miles. But also its not clear who is careful checking LDU for leaks. Leak doesn't mean LDU is dead immediately. It depends on how much leak rate and how far leak progress inside LDU. It is difficult to find people willing to climb under the car, remove belly aero pan, check speed sensor even 2x/year.

I think the history of Tesla LDUs is early cars had LDU changed out frequently due to other problems (drive load clunk, non ceramic bearings micro arc welding noise) so reman process started quickly and unfortunately it seems to be a fairly poor reman effort. Therefore many car's LDU suffer from this problem but some people luckily never changed from original early new LDU and seem to have no leak for long periods.

Of course Tesla is now installing LDUs without rotor cooling. But this just started so the public do not yet have longevity data. I did quick research on how rotor fails with high thermal ( link )

I know this thread and openinverter threads are long with many posts. LDU coolant leak seems to be a science project for everyone including Tesla. Tesla found no solutions in 10 years after talking to many seal manufacturers (I talked to many, they all said Tesla / tier 1 supplier contacted) Eventually, not cooling rotor with coolant is the current solution after so many costly remans.

Last edited: