Wait, are those perforated?Big news from Tesla! @ Twitter

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Here’s my guess as to what Tesla probably knew:

1) Sales of the S and X were lagging and the designs inside were tired and less efficient given the 3 and Y designs.

2) They were going to refresh the vehicles

3) In order to refresh, they had to retool as described above, which meant taking S and X production offline for a quarter or so.

4) They knew how many 3 and Y orders they had for Q4 and Q1 delivery, and knew they’d meet/beat deliveries in Q4 and Q1.

5) So they shut down the line in December, announced the refresh in January knowing it would boost sales (orders) and jump start interest in the S and X.

6) Probably thought they’d be delivering in Q1 late or early Q2, realistically, but know they have enough 3 and Y orders and huge momentum in the stock to easily get through Q2 “unscathed” even if they can’t deliver. The S and X no longer carry the company.

They likely ran into some sort of delay(s) with the retooling, but know they’ve got plenty of time.

In short, they tried to time the shutdown and refresh with ramp up and delivery of Y and continued interest in the 3.

My “Estimated delivery” remains “-“.

1) Sales of the S and X were lagging and the designs inside were tired and less efficient given the 3 and Y designs.

2) They were going to refresh the vehicles

3) In order to refresh, they had to retool as described above, which meant taking S and X production offline for a quarter or so.

4) They knew how many 3 and Y orders they had for Q4 and Q1 delivery, and knew they’d meet/beat deliveries in Q4 and Q1.

5) So they shut down the line in December, announced the refresh in January knowing it would boost sales (orders) and jump start interest in the S and X.

6) Probably thought they’d be delivering in Q1 late or early Q2, realistically, but know they have enough 3 and Y orders and huge momentum in the stock to easily get through Q2 “unscathed” even if they can’t deliver. The S and X no longer carry the company.

They likely ran into some sort of delay(s) with the retooling, but know they’ve got plenty of time.

In short, they tried to time the shutdown and refresh with ramp up and delivery of Y and continued interest in the 3.

My “Estimated delivery” remains “-“.

What kind of video?What kind of videos is Tesla supposed to provide ? Elon watching Grimes get another tattoo ?

Let's be serious -- even if Tesla uploaded a video of a revised Model S waiting in the drive-thru line at In-n-Out -- we'd know nothing more than the driver was dying for a double-double.

Consumers are just looking for the facts - or at least a close facsimile.

Believe it or not -- even if Elon said - "We expect initial deliveries on June 1," but then back-tracked on May 15 and said he expected a delay, I'd probably roll my eyes and shrug, but would at least feel as if he was making an initial stab at customer communication.

But 'ya see... the way he's playing the game... he is purposely shielding himself from any accountability. Since the guy pretty much owns the company, he's only really accountable to that silly mug in the mirror. Just the way he likes it.

The performance numbers on the website are very impressive, almost unbelievably impressive. The video of the Plaid model S at Laguna seca 6 months ago was great to see. However, the regular plaid wasn’t announced at that time, so was that car a plaid plus? I doubt many people buying a plaid give a rats as** about how it drives in the snow. Just my opinion of course..

jsight

Active Member

Yeah, the initial cars were more like the middle of the pack. The SR+, SR, and even the limited edition MR came later.It was my understanding the $35,000 base model that was promised wasn’t produced for quite a while. You are probably correct that AWD wasn’t produced first (probably wasn’t even initially available) and perhaps the same with performance, by my recollection was nothing below $50k left the factory for quite a while. If not performance at least high content cars.

Hayseed_MS

Spreader of "Endless Non Sequitur"

As an engineer who has to ferry products through the certification and manufacturing process, I'd offer a couple of comments on this:

That was bound to be painful, but I'd much rather wait until they have more kinks ironed out than get vehicle #4 off the line and it shifts into reverse every 10th time I turn left, or the bumpers to fall off if I hit a speed bump over 5MPH, or whatnot. Rushing the testing process is the worst thing they can do, especially if they're finding lots of things to fix. Would you rather have your Model S now and it's garbage that's constantly broken, or get it in late July but it's driveable? A legacy company like Volkswagen or Ford has the resources to set up a dedicated line for an incremental model year release, make a run of test articles, and abuse them for half a year or so before public release, and are still perfectly capable of releasing cars with embarrassing and highly annoying problems. If Tesla doesn't have the resources for a parallel line, they just have to deal with embarrassing and highly annoying problems plus embarrassing and highly annoying delays.

Isn't that part of the AI autoshift Elon was talking about?

eipi10

Member

As an engineer who has to ferry products through the certification and manufacturing process, I'd offer a couple of comments on this:

- Did they not know they needed the tooling? Yes, but until the tooling has been procured, installed, and tested, you don't know if the tooling you designed is the tooling you received, or if it's the tooling that you wanted. If something is wrong, you have to modify the tooling or (worse) design, procure, install, and test new tooling. If the tooling is very expensive, there's possibly going to be a lot of fighting over who has to pay for these modifications.

- Did they not know they needed approval for the yoke? There's been a lot of back and forth about the yoke but does anyone actually know what the story is here? I don't - and don't claim to - but I buy the argument that NHTSA doesn't pre-approve stuff like this, but can require changes if its too far off the wall, or its use results in a pattern of mishaps. Manufacturers can head off issues by coordinating in advance, but unless Tesla did this and NHTSA said "lol no" I really don't see this as being part of the issue. They've got a round steering wheel, so if the shape of the yoke was a problem they could get around it. Having PRND controls in a non-standard part is clearly not a problem; car manufacturers put those in a lot of places now.

- Did they not know chips would be hard to get? I'm dealing with this [heck] right now. Knowing that components (not just chips; also passive components) are hard to get doesn't mean knowing which ones are hard to get, and when. Stuff can be available in the tens of thousands while you're designing a module, then suddenly evaporate when it's time to build it. Lots of companies are pre-purchasing/hoarding now too, which makes it worse.

Tesla could calm a lot of nerves by just telling people where they're at in the process, but in the absence of that I'd look at the available evidence, which is that they stopped the old assembly line, put the new line together, made a handful of test articles (which people are seeing on the road), and don't appear to be making more. The cars that people spot in the wild frequently have pieces missing, one of at least a couple of steering wheels, debugging connectors hanging out, FACTORY MODE displayed on the screens, etc. So now they're clearly testing.

There's a lot to test in a new car, and a lot to go wrong, and they've got to have an army of test engineers putting a lot of miles on a lot of cars (hitting all of the major variations) in a lot of different environments. They seem to be doing this and I think it's reasonable to guess that so much is broken right now that it would be profoundly stupid for them to release cars to consumers. That's not to say TESLA BAD - just that these are really complex, sometimes unprecedented products and there's a lot to go wrong, and a lot of testing has to happen before they foist them on paying customers. Rushing the engineering phase could be to blame for some/many problems, but they also can't put miles on test vehicles until they've manufactured them, ideally on the actual production line, and if they don't have the resources to have the new line assembled and usable in parallel with the old one, they have to stop making Model S cars at some point to start this process, and now they can't deliver Model S cars until the process has completed.

That was bound to be painful, but I'd much rather wait until they have more kinks ironed out than get vehicle #4 off the line and it shifts into reverse every 10th time I turn left, or the bumpers to fall off if I hit a speed bump over 5MPH, or whatnot. Rushing the testing process is the worst thing they can do, especially if they're finding lots of things to fix. Would you rather have your Model S now and it's garbage that's constantly broken, or get it in late July but it's driveable? A legacy company like Volkswagen or Ford has the resources to set up a dedicated line for an incremental model year release, make a run of test articles, and abuse them for half a year or so before public release, and are still perfectly capable of releasing cars with embarrassing and highly annoying problems. If Tesla doesn't have the resources for a parallel line, they just have to deal with embarrassing and highly annoying problems plus embarrassing and highly annoying delays.

I'd still love to get my Model S tomorrow, but ... I can wait. What I'd love even more is if they would just let people know where they're at. But if where they're at is "EVERYTHING IS BROKEN AND NOBODY HAS SLEPT SINCE FEBRUARY" then I kinda see why they're not really sharing that.

This all makes sense...except, Tesla said deliveries would start in February, and my account still has an expected delivery of "March." So what you're asking me to accept is either: (1) Tesla is ignorant about everything you said above; or (2) Tesla lied about when its product would be available. In my opinion, Tesla should have done all the testing you're describing before offering a product for sale and representing to customers that delivery would occur in a month. Now for me personally, it doesn't matter. I haven't owned a car in many years. I don't need one. But I don't like being screwed around with by an unethical company.

This is a nonsensical paragraphNow for me personally, it doesn't matter. I haven't owned a car in many years. I don't need one. But I don't like being screwed around with by an unethical company.

aerodyne

2 of 3 EV's - Defect Free!

I think the OP was joking, as that is the Dark Helmut line from Spaceballs, you know, the one they got plaid from...That’s great news! When did you order?

cascadilla

MSLR Red/Black/FSD/19" 3/23 RN1146, MF443, 9/27

We’ve yet to see any refreshed Model X in the wild, which makes me wonder if they’re actually further out than it seems. Model S was going to come first, but supposedly X was just a month behind.

MagnusMako

Member

As an engineer who has to ferry products through the certification and manufacturing process, I'd offer a couple of comments on this:

- Did they not know they needed the tooling? Yes, but until the tooling has been procured, installed, and tested, you don't know if the tooling you designed is the tooling you received, or if it's the tooling that you wanted. If something is wrong, you have to modify the tooling or (worse) design, procure, install, and test new tooling. If the tooling is very expensive, there's possibly going to be a lot of fighting over who has to pay for these modifications.

- Did they not know they needed approval for the yoke? There's been a lot of back and forth about the yoke but does anyone actually know what the story is here? I don't - and don't claim to - but I buy the argument that NHTSA doesn't pre-approve stuff like this, but can require changes if its too far off the wall, or its use results in a pattern of mishaps. Manufacturers can head off issues by coordinating in advance, but unless Tesla did this and NHTSA said "lol no" I really don't see this as being part of the issue. They've got a round steering wheel, so if the shape of the yoke was a problem they could get around it. Having PRND controls in a non-standard part is clearly not a problem; car manufacturers put those in a lot of places now.

- Did they not know chips would be hard to get? I'm dealing with this [heck] right now. Knowing that components (not just chips; also passive components) are hard to get doesn't mean knowing which ones are hard to get, and when. Stuff can be available in the tens of thousands while you're designing a module, then suddenly evaporate when it's time to build it. Lots of companies are pre-purchasing/hoarding now too, which makes it worse.

Tesla could calm a lot of nerves by just telling people where they're at in the process, but in the absence of that I'd look at the available evidence, which is that they stopped the old assembly line, put the new line together, made a handful of test articles (which people are seeing on the road), and don't appear to be making more. The cars that people spot in the wild frequently have pieces missing, one of at least a couple of steering wheels, debugging connectors hanging out, FACTORY MODE displayed on the screens, etc. So now they're clearly testing.

There's a lot to test in a new car, and a lot to go wrong, and they've got to have an army of test engineers putting a lot of miles on a lot of cars (hitting all of the major variations) in a lot of different environments. They seem to be doing this and I think it's reasonable to guess that so much is broken right now that it would be profoundly stupid for them to release cars to consumers. That's not to say TESLA BAD - just that these are really complex, sometimes unprecedented products and there's a lot to go wrong, and a lot of testing has to happen before they foist them on paying customers. Rushing the engineering phase could be to blame for some/many problems, but they also can't put miles on test vehicles until they've manufactured them, ideally on the actual production line, and if they don't have the resources to have the new line assembled and usable in parallel with the old one, they have to stop making Model S cars at some point to start this process, and now they can't deliver Model S cars until the process has completed.

That was bound to be painful, but I'd much rather wait until they have more kinks ironed out than get vehicle #4 off the line and it shifts into reverse every 10th time I turn left, or the bumpers to fall off if I hit a speed bump over 5MPH, or whatnot. Rushing the testing process is the worst thing they can do, especially if they're finding lots of things to fix. Would you rather have your Model S now and it's garbage that's constantly broken, or get it in late July but it's driveable? A legacy company like Volkswagen or Ford has the resources to set up a dedicated line for an incremental model year release, make a run of test articles, and abuse them for half a year or so before public release, and are still perfectly capable of releasing cars with embarrassing and highly annoying problems. If Tesla doesn't have the resources for a parallel line, they just have to deal with embarrassing and highly annoying problems plus embarrassing and highly annoying delays.

I'd still love to get my Model S tomorrow, but ... I can wait. What I'd love even more is if they would just let people know where they're at. But if where they're at is "EVERYTHING IS BROKEN AND NOBODY HAS SLEPT SINCE FEBRUARY" then I kinda see why they're not really sharing that.

I agree with most of your points. However regarding testing - I'd wager much of the new S core technology and structure is still much the same. The body shape looks nearly identical to the current one, aside from the front fascia tweaks and some trim changes around the rear. The underpinnings are probably all the same other than some suspension upgrades. The batteries are just an updated version of their current cells using tweaked chemistry. I'd imagine the majority of testing is thermal and going into whatever cooling system they're using (assuming it has been changed as well). The screen itself probably doesn't need much changing on the back end either. There are way way more variables with the amount of moving parts to deal with in traditional ICE cars. And Tesla already has the software part down extremely well so they don't have to worry too much about that and the various sub systems. I'd imagine the chip delays is causing them to just refocus production on their bottom line while giving ample time to thoroughly test the new S until the shortages dampen.

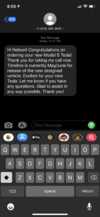

Just adding my data point…

Called Tesla today (logistics/vehicle delivery)

I was told May/June. I asked if this was specific to my reservation number or just a stock response that everybody would be getting. I told him “I assume there must be a pretty large backlog at this point.” And he responded yes to the backlog and that May/June was specific to my reservation number. RN114620xxx

Placed 3/11/21

I also asked him if he had any idea why there was such a delay and he said he didn’t know.

VIN Specific! That means they have the information to display it on the webpage but haven't updated it. Interesting.

My delivery still says March. At this point I'm just checking in periodically. I guess I'll expect May/June.

What I find amazing is that the same company that can put up an enormous plant from scratch in another country and get it online in record time can’t tell us when a ‘refreshed’ S will come off the line of an established factory.

Hey, I love Tesla but some things boggle my simple little noggin.

Hey, I love Tesla but some things boggle my simple little noggin.

Not sure if rear tire size has been posted. This photo looks like the rear has PILOT SPORT 4S - size - 295/30 ZR 21

Geebo324

Member

epotter

Member

I guess my point was that Tesla couldn't do the testing I described until after retooling the line, and if they've got to take the existing line down and not deliver any Model S cars for a few months they're gonna have to say why. Publicly dropping the refresh at that point at least creates buzz and may sway some fence sitters. That said - their delivery timeline was clearly quite optimistic.This all makes sense...except, Tesla said deliveries would start in February, and my account still has an expected delivery of "March." So what you're asking me to accept is either: (1) Tesla is ignorant about everything you said above; or (2) Tesla lied about when its product would be available. In my opinion, Tesla should have done all the testing you're describing before offering a product for sale and representing to customers that delivery would occur in a month.

As for the delivery timeline - what's the quote? "Lies, damned lies, statistics, benchmarks, and delivery dates." Any sales person will tell you that saying "we have this awesome product that costs around $100k but we don't know when it'll be done, maybe some time in the next year" isn't going to generate huge numbers of sales. I think (personal opinion!) the worst thing they could do is promise a delivery date, miss it, promise another one, miss that one too, promise a third, miss that one as well, etc. With each missed deadline, the pressure on the engineering side to call it "good enough to ship" grows and customers get less and less patient. You end up with a product that's delivered too early, with avoidable problems, and everyone is still pissed at you.

That's not to say that I think they're handling it right - promising a delivery date, missing it, and then completely failing to follow up on that is only slightly better than the string of missed deadlines, if only because there's only one broken promise.

It's hard for me to tell what's new; all I have are photos of the old S (that I tried to buy in December) and the new one (that I actually bought in December, apparently) from their web site. I'd agree that a lot of core technology (battery, motor drives, etc) is probably pretty similar, though isn't the rear body somewhat different? Beyond the spacing of the rear wheels, how much of it is cast vs stamped/welded? I thought I saw some speculation that there were larger single pieces back there. Also a lot of smaller details like fit/finish on interior parts are really, aggravatingly difficult to get right. Making all of those trim lines match reasonably well from one front door to the dash to the other front door, and not squeak and rattle, is tough. Is that why so many of the test cars are missing interior trim?I agree with most of your points. However regarding testing - I'd wager much of the new S core technology and structure is still much the same. The body shape looks nearly identical to the current one, aside from the front fascia tweaks and some trim changes around the rear. The underpinnings are probably all the same other than some suspension upgrades. The batteries are just an updated version of their current cells using tweaked chemistry. I'd imagine the majority of testing is thermal and going into whatever cooling system they're using (assuming it has been changed as well). The screen itself probably doesn't need much changing on the back end either. There are way way more variables with the amount of moving parts to deal with in traditional ICE cars. And Tesla already has the software part down extremely well so they don't have to worry too much about that and the various sub systems. I'd imagine the chip delays is causing them to just refocus production on their bottom line while giving ample time to thoroughly test the new S until the shortages dampen.

Another question would be about the electronics that spin the motors. The Plaid and (in particular) Plaid+ versions are going to be pushing more power to the rear motor(s) than previous models. If they're trying to use the same inverters for LR/Plaid/Plaid+, that's going to be somewhat new and I can definitely say that you have to test the heck out of motor drivers, especially high voltage/power ones, because they can fail in spectacular ways for bizarre reasons and lab testing only gets you so far.

Actually - speaking of electronics, I'd be willing to wager that they took some of the innovative things that launched with the Model 3 and fitted them into the S. The Model 3 is almost definitely more cost-optimized than the S, and one hopes they would take those lessons learned and apply them. So there may be more small details that are new for the S, at least, than are immediately visible. Granted, those are 'existing' items that have some testing behind them, but integration always brings new challenges.

UI software is going to be somewhat different since the screen rotated, but that's probably not a huge leap, and the visual layout stuff really should have been basically done months ago. But no telling if someone got a wild hair and decided to refactor a bunch of old code to unify Model S/3/X/Y codebases, which is going to extra work in the beginning.

Delays on getting electronics is certainly plausible as a contributing factor or at least a convenient excuse, but I can't imagine that it's the only issue, especially if they're not having the same problems on other models.

Eh. Until the car arrives, speculating is the most fun I'm gonna have!

Thank you, we’ve been speculating for a while about the rear tire size. Love the refresh in blackNot sure if rear tire size has been posted. This photo looks like the rear has PILOT SPORT 4S - size - 295/30 ZR 21

Similar threads

- Replies

- 14

- Views

- 2K

- Locked

- Replies

- 66

- Views

- 8K

- Replies

- 47

- Views

- 6K

- Replies

- 2

- Views

- 518